Model Based Approach¶

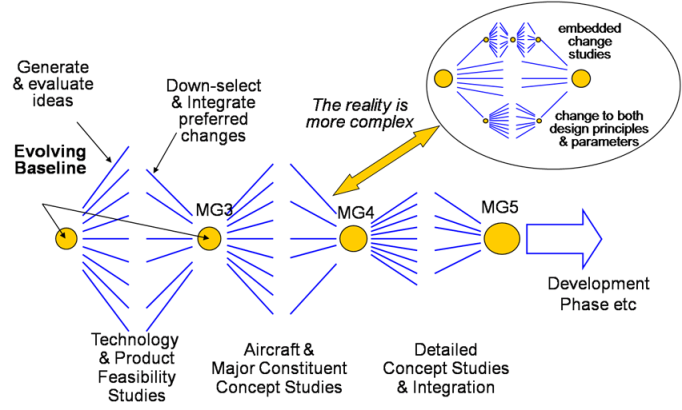

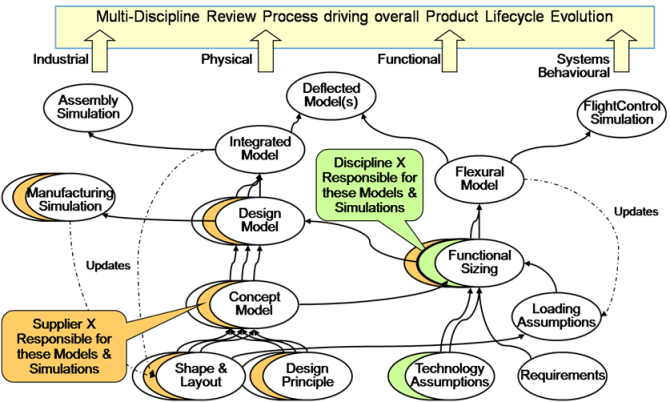

During product conception and definition, engineers use a variety of tools to develop networks of interdependent models that represent, analyse and simulate the design and behaviour of different aspects of the aircraft. These models evolve in maturity and detail as the design progresses

The model network is in effect an explicit single representation of both the design process and the resultant product information. The network is elaborated as design topics are addressed, and network templates are prepared in readiness for key activities. The network records the types of models used, their interdependencies, tools, skills and the resources required to create the models and update them as the design evolves. Today, individual teams within an enterprise exploit the models-based network approach to cascade changes rapidly into the models and simulations they are accountable for. However, the traditional organisation and information systems deployed at enterprise level typically separate the two key aspects of design process and product information management, so it is not possible to realize the full benefits of the models based approach at the team of teams level. In particular:

- Models are owned (see below) by different:

- people

- departments

- engineering disciplines

- Companies

Models are created/maintained by a variety of IT frameworks

Models need to share/exchange information

Therefore, there is a need to define a common approach to enable collaboration between the models.

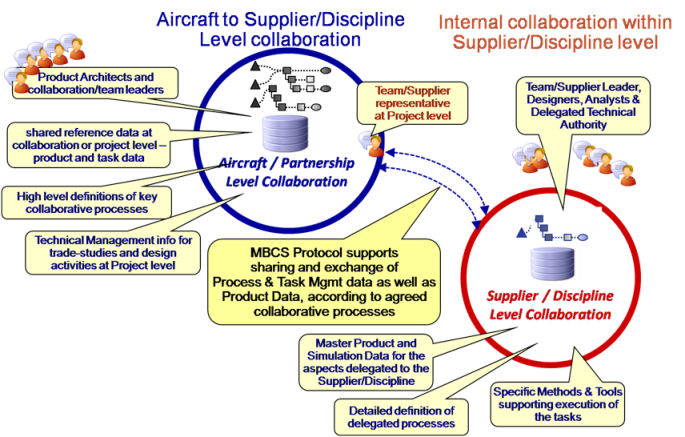

Models Based Collaboration Services (MBCS)¶

Some companies are adopting the concept of “models based collaboration services” (MBCS) as a means to realize the benefits of the models-based approach at the enterprise level by addressing the topics of collaborative design process management and collaborative product information management together from a unified life-cycle management perspective. Competitive global enterprises exploit a heterogeneous mix of different and evolving software solutions. Therefore the MBCS concept has been elaborated in the form of a protocol or standard – identifying how the collaborating teams should interact rather than specifying the software tools they should use. This approach utilises the ISO 10303-239 Product Life Cycle Support and ISO 10303-233 Systems Engineering standards, and associated PLCS PLM Web Services, and can be interpreted and applied to represent the information and services required to support such models-based collaboration. This approach builds on the concept of a Virtual Enterprise Collaboration Hub (VEC-hub ™) for supporting collaborative design in the extended enterprise developed as part of European funded VIVACE R&D project

The above image shows a typical use of the MBCS protocol to enable collaborative working between an OEM and a supplier. It also highlights other collaborative processes and data that must be managed by a BDA. Therefore, in order to support the models based design approach in an extended enterprise, the BDA must:

- Support a heterogeneous business environment in which different business processes are deployed and different IT systems used

- Enable a flexible network of partners where partners may collaborate and compete, hence the architecture ensures that the information is secure and that different partners IPR is respected by managing the clear ownership of data, methods and knowledge

- Manage and provide data to partners, respecting the security and ownership of data and ensuring that the data is placed under configuration management

- Support the collaborative work processes by providing services that notify partners of relevant events (changes) to the shared information

- Enable the execution, coordination and evaluation of trade studies in which the design and analysis activities are distributed across the enterprise

- Enable the representation of a network of models, both abstract network patterns, and the resulting networks that evolve as part of the trade study

Engineering Capabilities Management perspective¶

Engineering Capabilities Management involves understanding the deployable services within a business. It involves understanding the strengths, weaknesses, opportunities and where scarce resources can best be deployed.

Traditionally businesses define capabilities in terms of process models that are represented as sequenced tasks. Such representations are suitable at the detailed mono discipline level. However, at the Multi-disciplinary level and extended enterprise level, such representations are more difficult to capitalise upon. Task representations are more difficult to assemble into new capabilities than the models that the tasks deliver.

By modelling capabilities in terms of the information delivered (models), an OEM and its supply chain can refine their working practices and improve collaboration and integration opportunities. One of the key benefits of the Model Based Approach is that it is possible to create a single graph of the process, information, methods and tools. Traditional approaches involve separate mapping of the process view and the information view which become unsynchronised.

The Model Based Approach supports Aircraft Architects and Team leaders responsible for concept evaluations and trade studies that require collaboration and the input from numerous domains. Team leaders can construct new capabilities quickly by assembling appropriate model networks that deliver information to validate concept suitability.

The Model Based Collaboration Analogy¶

The model based Collaboration approach is analogous to food preparation and cooking in the kitchen of a large restaurant.

The Common Models are the ingredients which in isolation serve very little purpose. The Executive Chef is the Aircraft Architect and the Sous-Chef (second in command) is a Team Leader. The Sous-Chef is responsible for overseeing the Chef de parties or station chefs.

Station chefs are responsible for the specialisation or deep disciplines and include the Fish Chef, Roast Chef, Vegetable chef, Pastry Chef and so on.

Finally the Kitchen is the Collaboration Environment. The kitchen is where customer orders are fulfilled by assembling models (ingredients) into the finished dish. The ingredients in isolation provide little benefit, but the collaboration that takes place within the kitchen directs effort to deliver new creations.