Illustrative Example - Ad-hoc Design Study¶

Overview¶

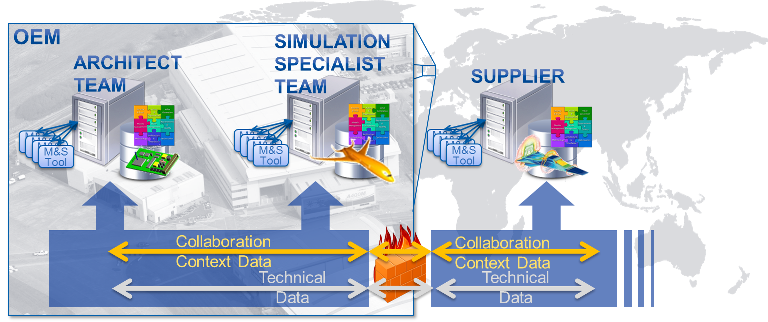

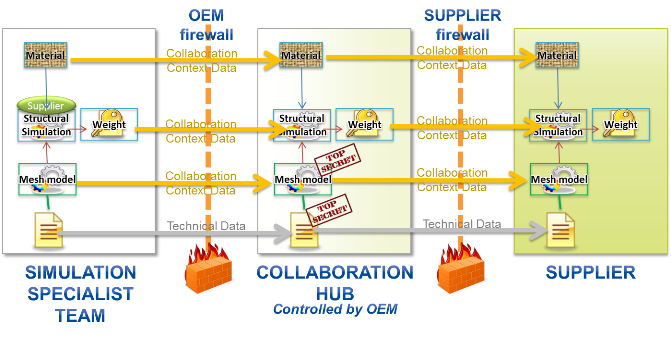

The following illustrative example shows a typical scenario of managing an ad-hoc study between two internal domain teams using different platforms (e.g. Architects using Dassault Systèmes’ 3D Experience platform and Simulation Specialists using MSC Software’s SimManager platform) and an external supplier (e.g. using Siemens’ TeamCenter platform). It is recognized that this does not cover the entire range of scenarios, and is only one of many use-cases which will be elaborated as part of the Application Activity Model.

The use case has the following steps:

- Initiate design investigation Study

- Prepare Study

- Perform Study

- Review Study

- Initiate follow-up Study

Initiate design investigation Study¶

During the concept phase of a new product family, an OEM Architect looks at the physical characteristics and performance simulation results for the current product and notices that:

- Recent advances in materials technology have provided significant weight benefits on another product family which may be transferable to the new family.

- The Architect [Team A], views simulation models from the structures experts [Team B] finding results for the new product that used properties of traditional materials, and also results for the other family that used the new material. It is seen that new material simulation results were provided by the material specialist [Supplier].

- The early simulations were conservative when compared to the physical testing resulting in an over engineered product. Therefore improvements in the simulation should be investigated.

- Architect, Team A, views simulation models from the simulation experts, Team B, and physical test results from Team C (not shown).

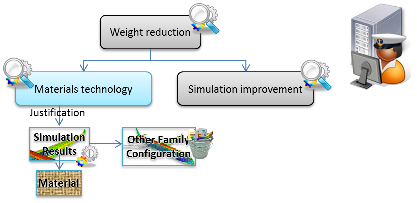

The OEM Architect decides to launch a top level “weight reduction” study controlling two parallel studies, “Materials Technology” and “Simulation Improvement”, to investigate these ideas. This is illustrated below:

Note

Only the “Materials Technology” study will be elaborated in this illustrative example.

Prepare Study¶

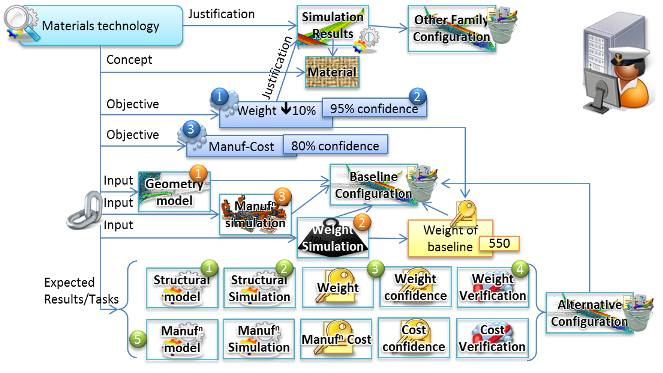

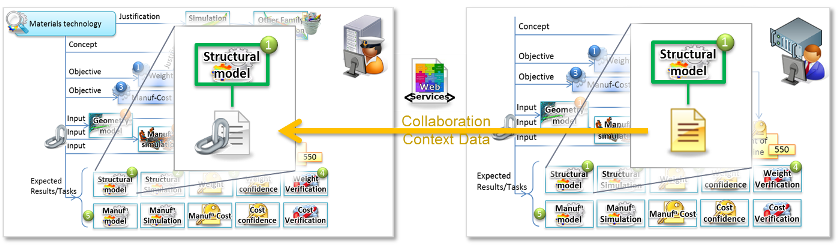

Using the architect’s software platform, the OEM Architect creates a “Materials Technology” study with the following:

Context: Managed by the “Weight Reduction” study.

Justification: Results from using this new material technology on other product families have shown significant improvements.

Concepts: New material technology

- Objectives:

- Calculate the weight of the product with the goal of a 10% reduction from the baseline, this target is justified by achievements seen in other product families.

- Weight calculation results are to be within a 95% confidence level (i.e. accurate)

- Calculate the impact on the manufacturing cost (time and materials) within an 80% confidence level (i.e. rough estimate)

Constraints: Product outer shape remains fixed, though the internal structure can change

- Inputs (as links to models on the Simulation Experts’ platform):

- Geometry models for the outer shape

- Weight simulation results from baseline

- Manufacturing models from baseline

The OEM Architect then sets up a review with the OEM Simulation Experts in “Team B”, with the results that the following high level tasks are identified for the study.

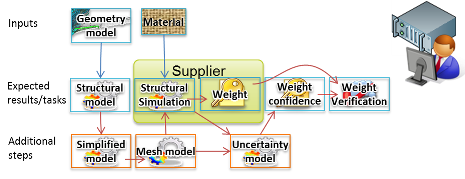

- Tasks (ad-hoc because methods are unknown)

- Generate a new structural model that is suitable for the new material.

- Generate structural simulation results from the new structural model [delegated to Supplier]

- Compute weight with associated confidence level

- Verify weight and confidence are within specified limits

- Compute manufacturing time and materials with associated confidence level

Perform Study¶

Review Study¶

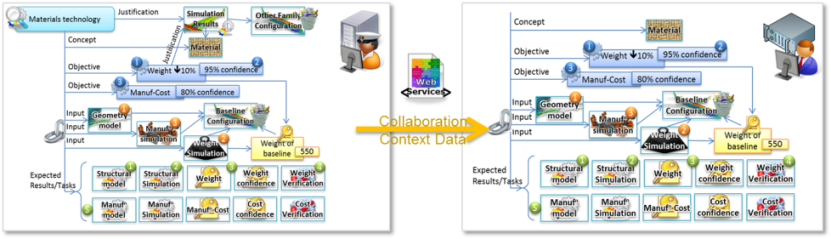

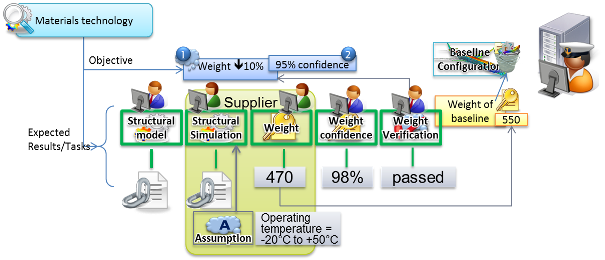

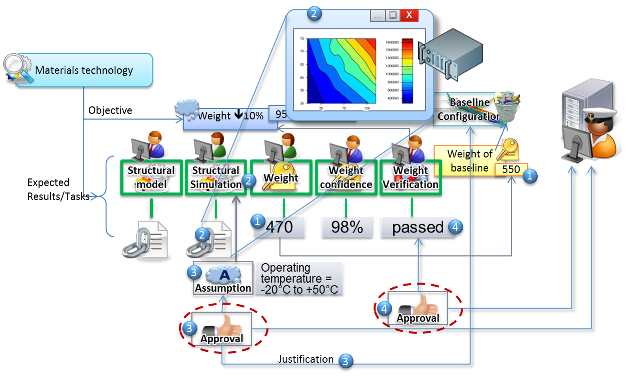

At any point in the life cycle of the study the OEM Architect can review the progress and any available results. In the figure below it is assumed that all the results have been published and the OEM reviews the following:

- Weight value, sees that it is significantly improved from the baseline and wants to review how this was achieved.

- Notices that the weight is computed from Structural Simulation results, so looks to see what simulation method was used to generate these results. Next chooses to look at the technical results in detail so clicks on the link to the results in the specialists’ software platform. This opens a window in the architect’s software platform with a viewer for the results.

- Notices that the supplier has added an assumption about the operating temperature range, opens the details of that assumption, decides that it is valid, and adds an approval to the assumption (perhaps also adding a justification to explain that it is valid because this baseline is within this range).

- Notices that the verification of the objectives have been set to “passed”, so signs off the approval for that verification.

The OEM Architect reviews the progress of any available results As the results from the other parts of the study become available the OEM Architect discovers that although the weight is improved by using the new material technology, the manufacturing cost has been significantly increased. By looking at the costs in more detail it becomes apparent that one part of the structure has more impact on these costs than the rest.

Initiate follow-up Study¶

The OEM Architect decides to launch a follow-up study where the part of the structure that had highest impact on the manufacturing cost uses conventional materials and the rest of the structure uses the new material. A review of the traceability from the different studies shows that the results from some of the intermediate steps can be reused (e.g. the simplified model and the mesh model) and other steps can use the same models to generate results from the updated inputs. Therefore a new study is launched that includes results from the previous studies and adds new tasks to rerun the results computation for the updated inputs.

Section author: Judith Crockford