The Very Simple Example¶

The name “very simple” is rather misleading. The problem is very simple, but the example has been expanded to illustrate many of the core features of the Business Object Model

Scenario Overview¶

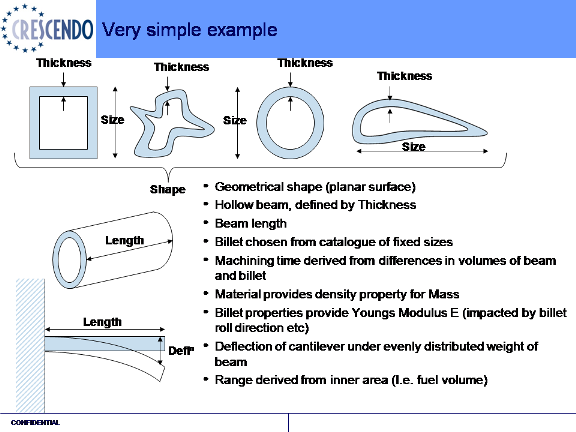

The scenario is illustrated below.

The aim is to compute the deflection of a beam.

The key features are:

- Geometrical shape (planar surface)

- Hollow beam, defined by Thickness

- Beam length

- Billet chosen from catalogue of fixed sizes

- Machining time derived from differences in volumes of beam and billet

- Material provides density property for Mass

- Billet properties provide Youngs Modulus E (impacted by billet roll direction etc)

- Deflection of cantilever under evenly distributed weight of beam

- Range derived from inner area (I.e. fuel volume)

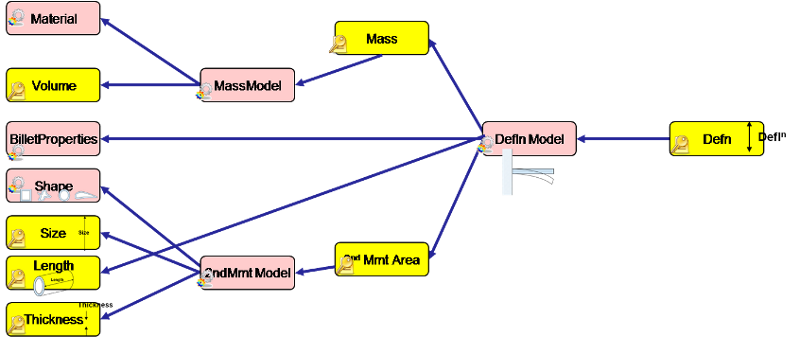

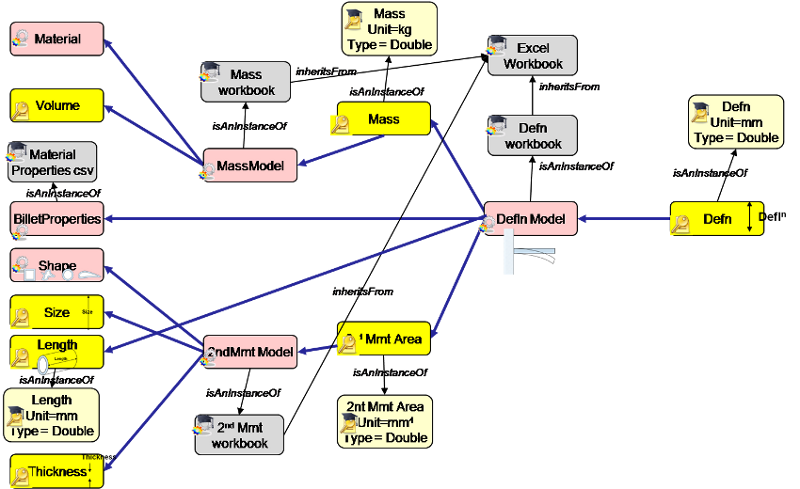

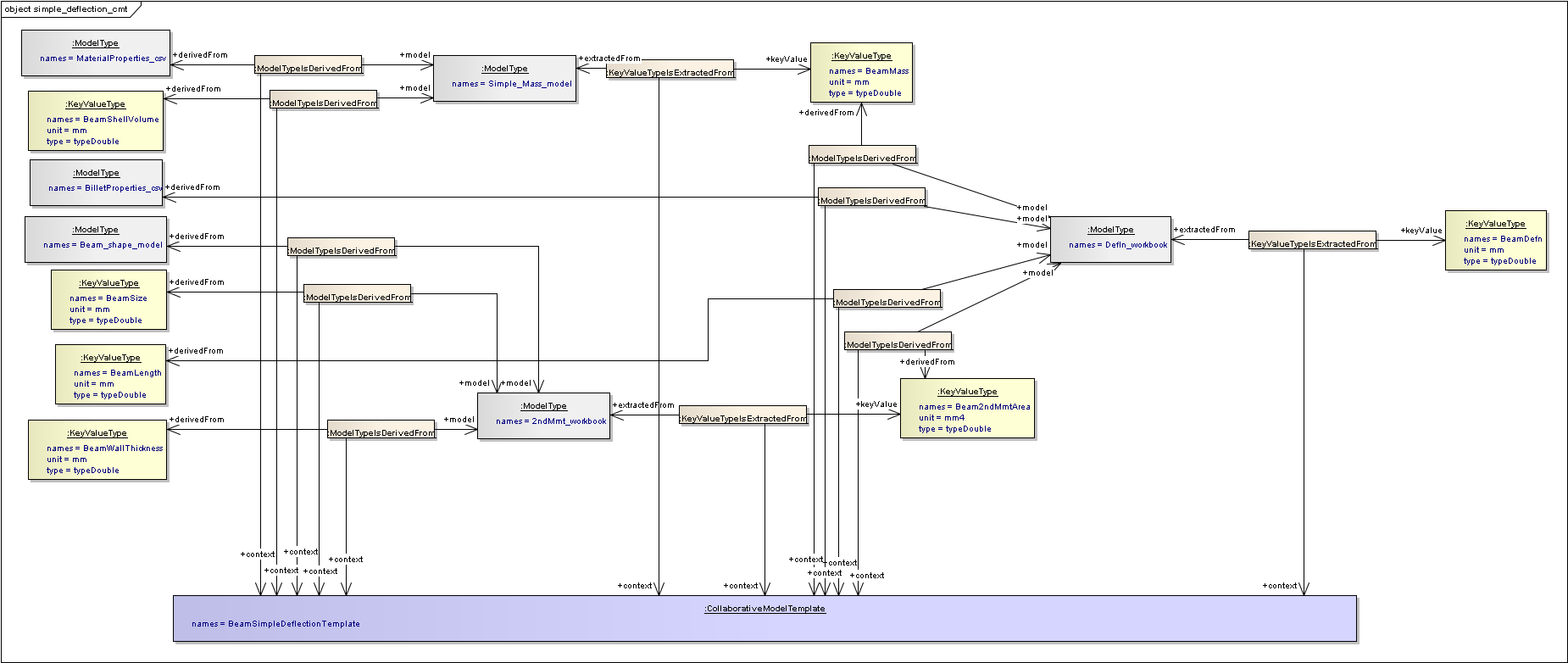

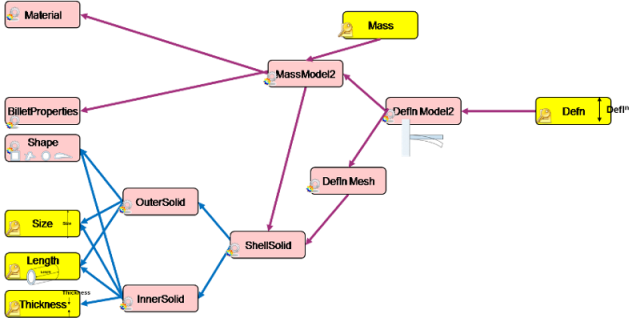

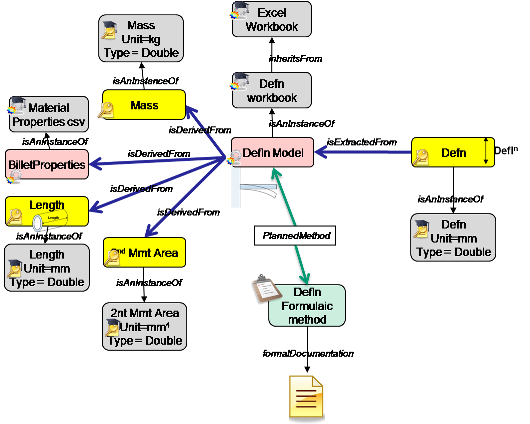

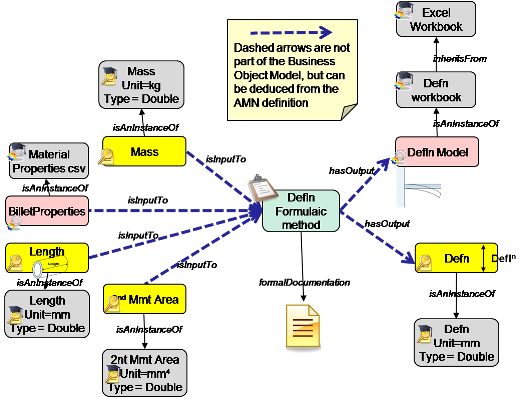

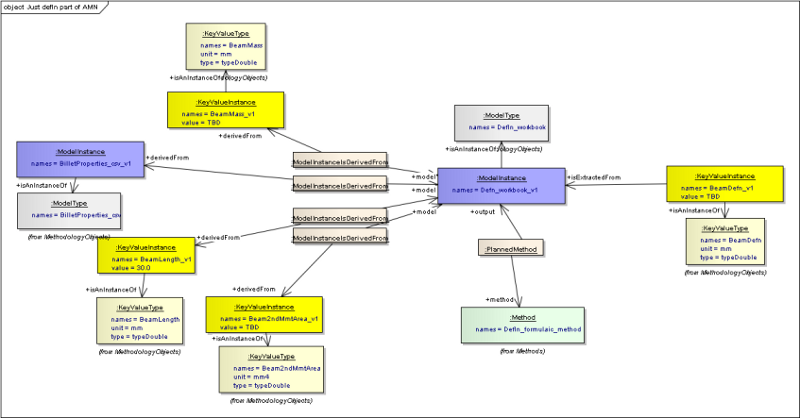

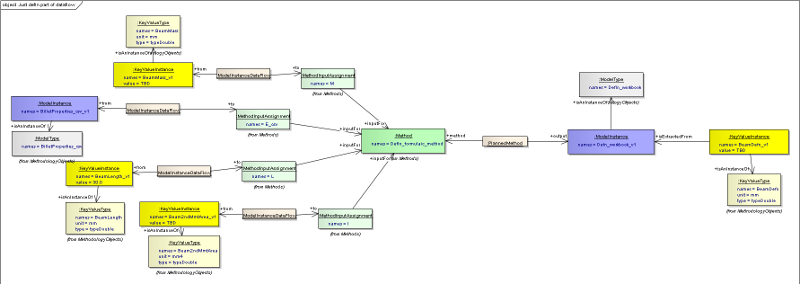

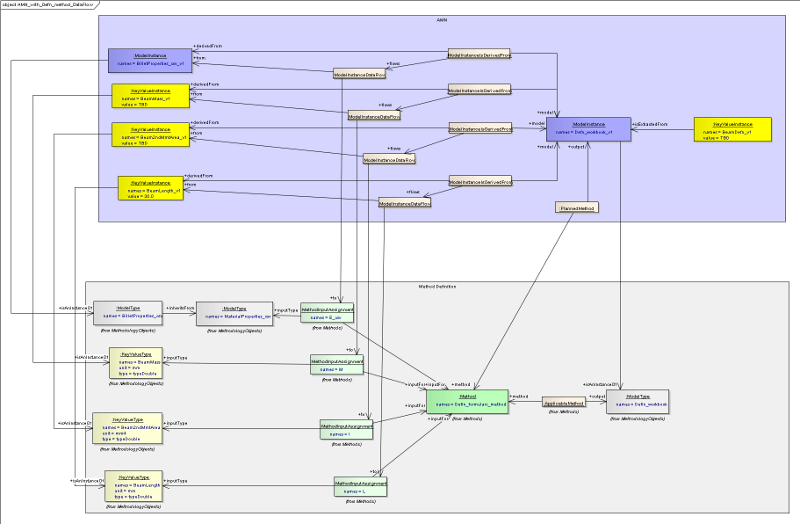

The Associative Model Networks [AMN]¶

The following are illustrations of the networks for the example

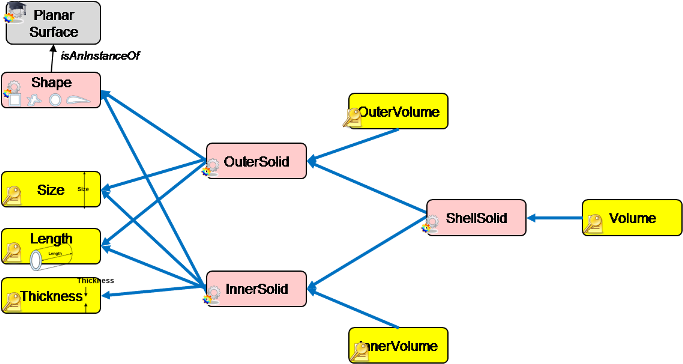

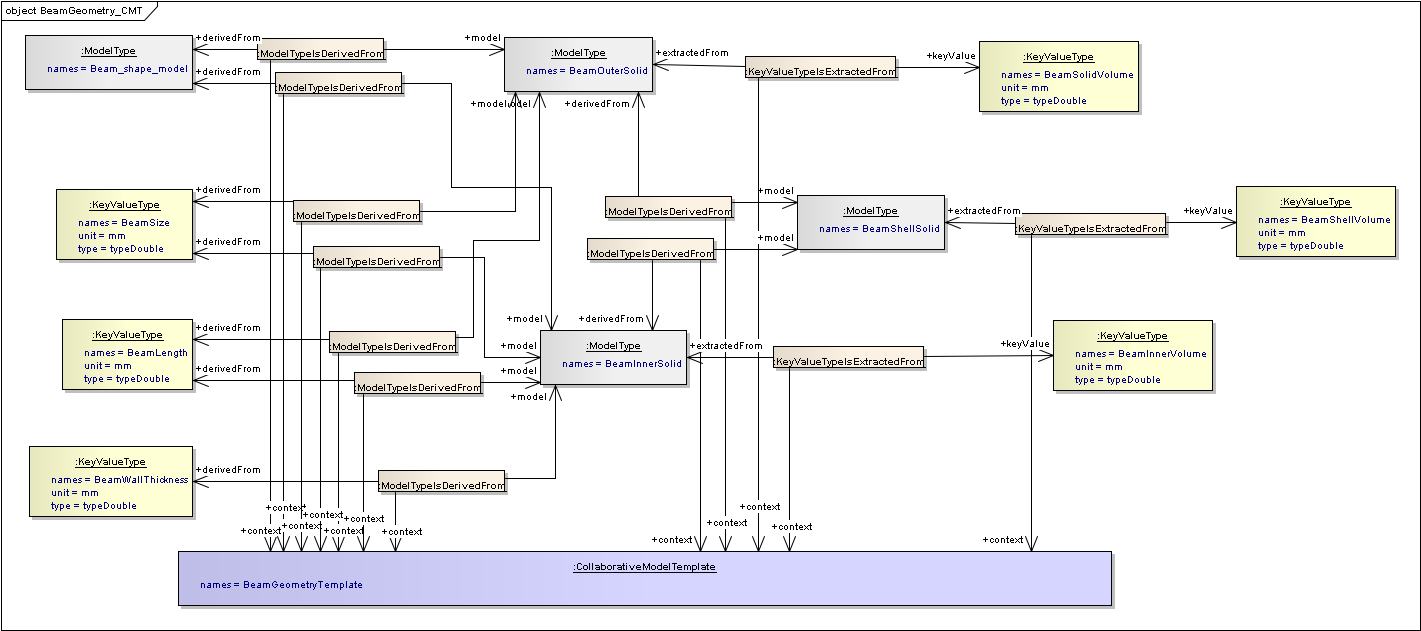

Beam Geometry AMN¶

The first stage is to create the geometry for the example. It is may appear to be overly complex for the simple problem, but this is to enable illustrations of other areas. The first image shows the network and the

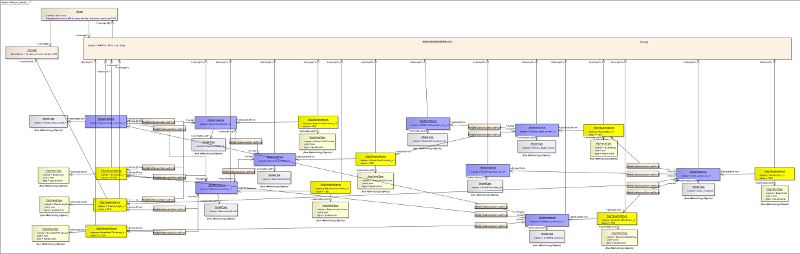

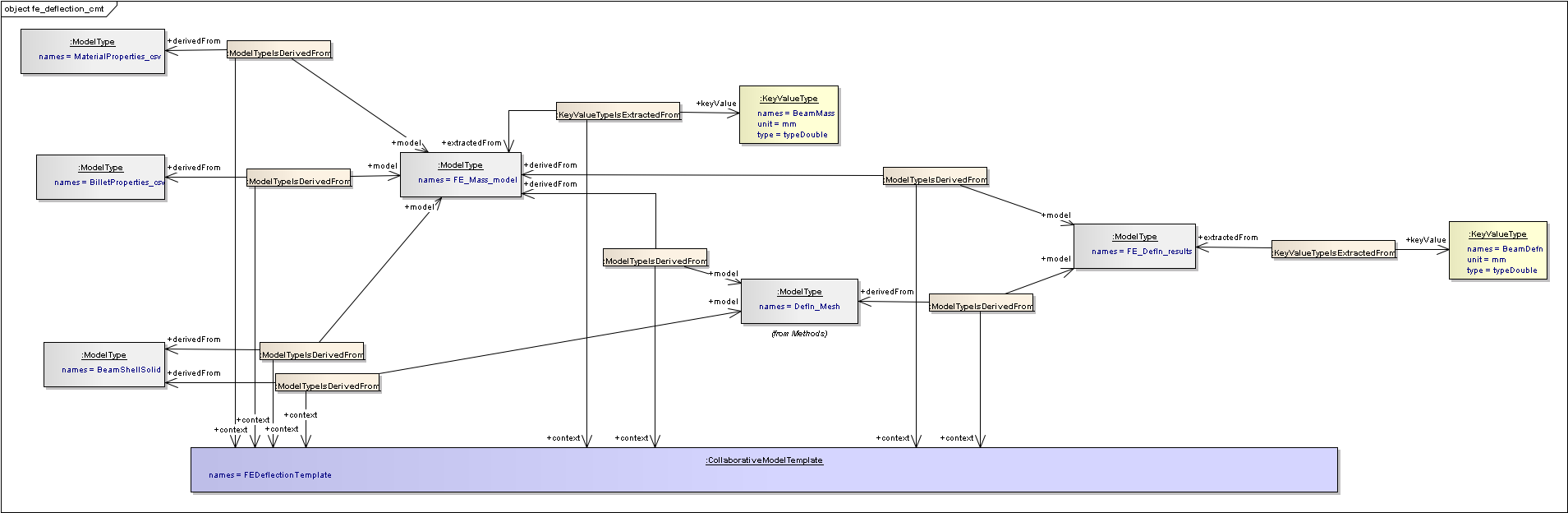

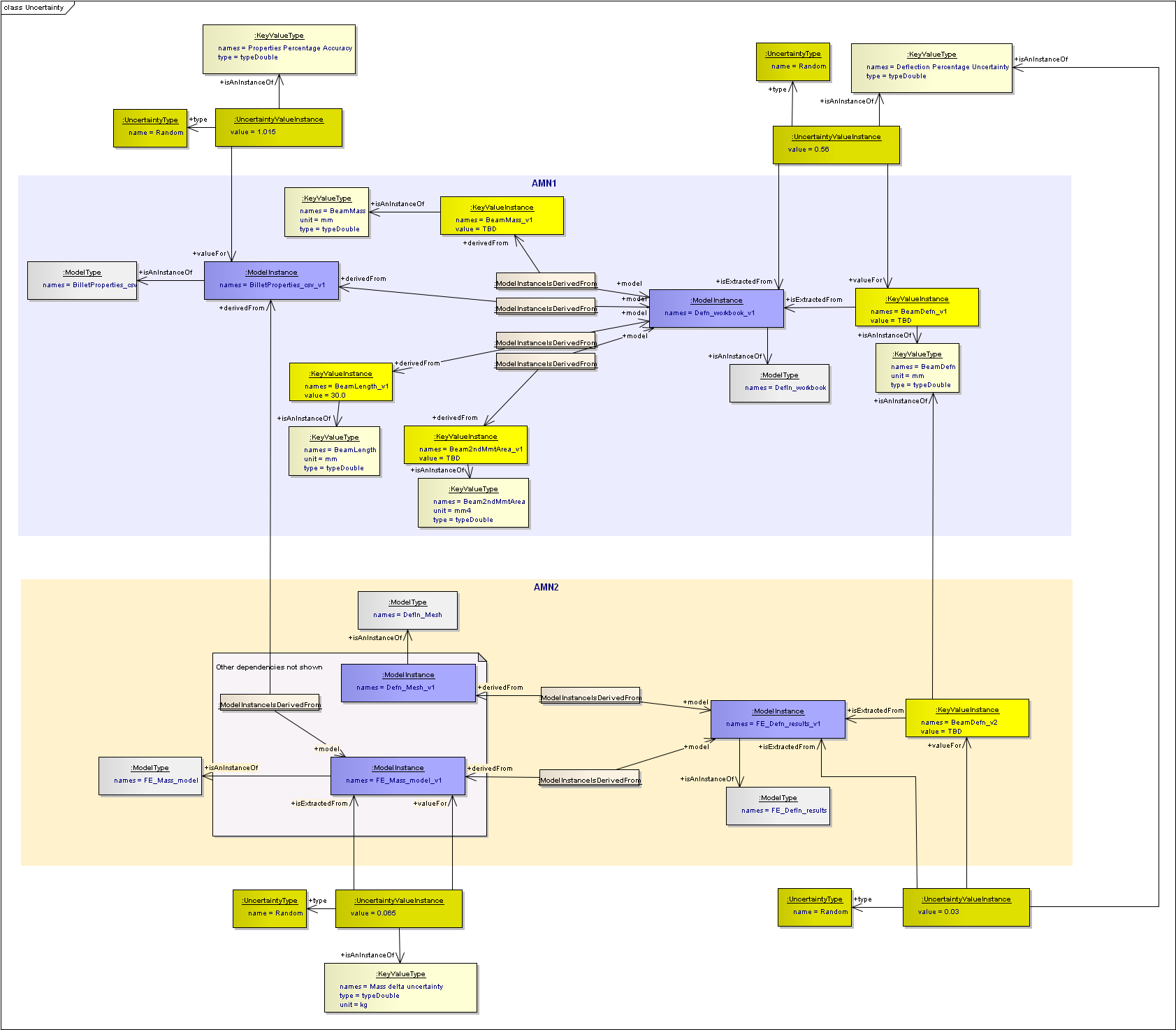

Deflection AMN¶

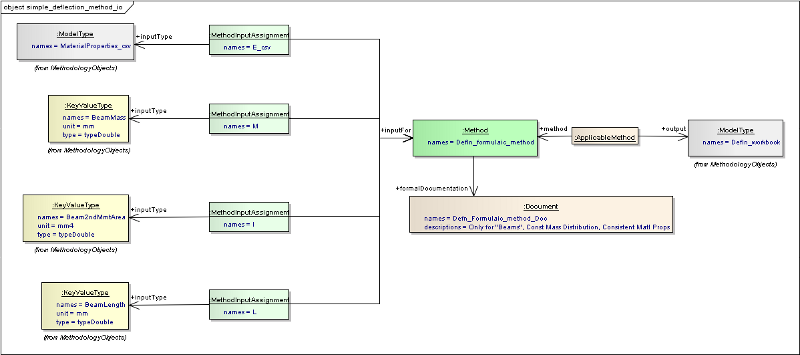

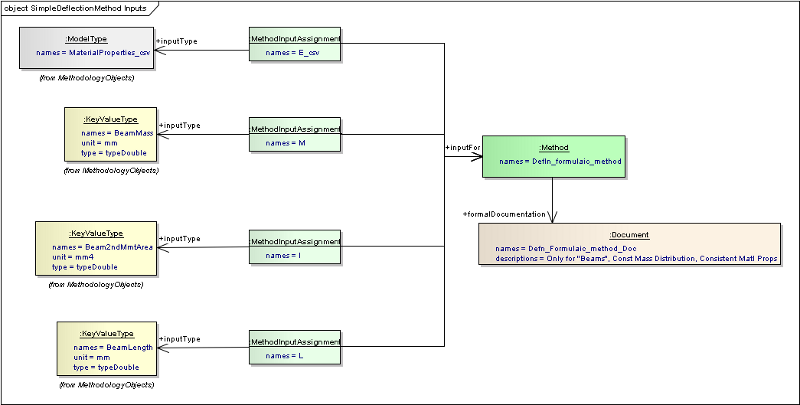

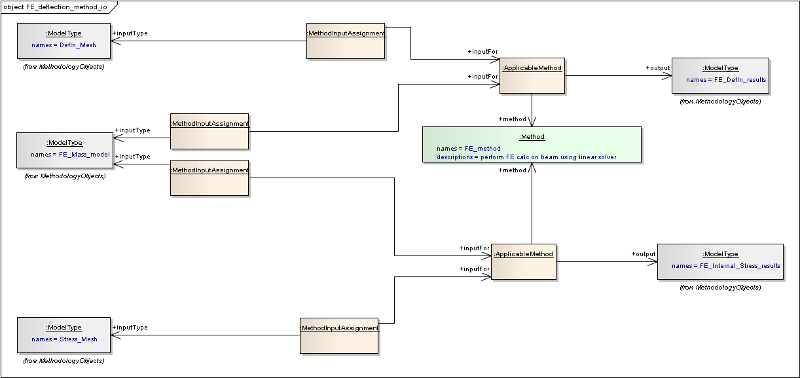

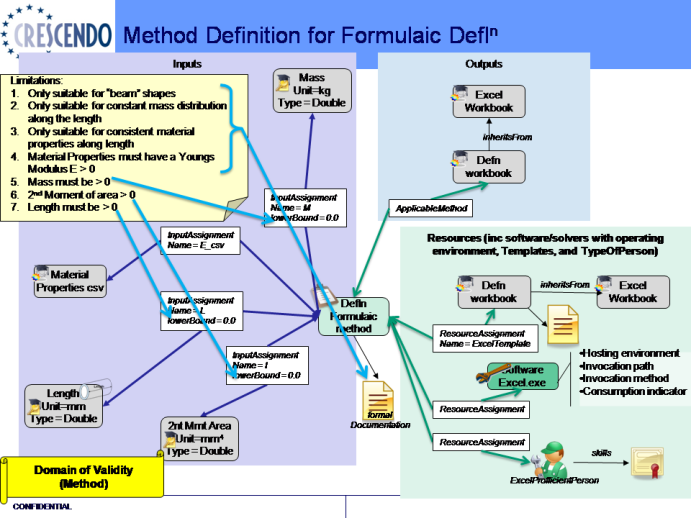

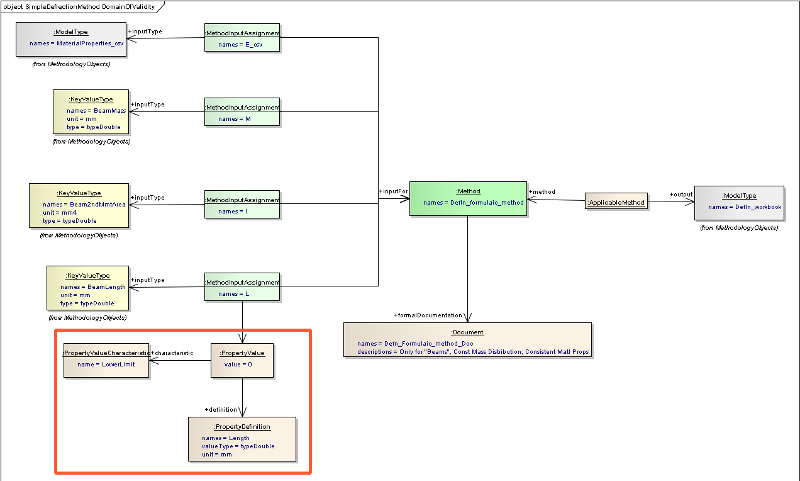

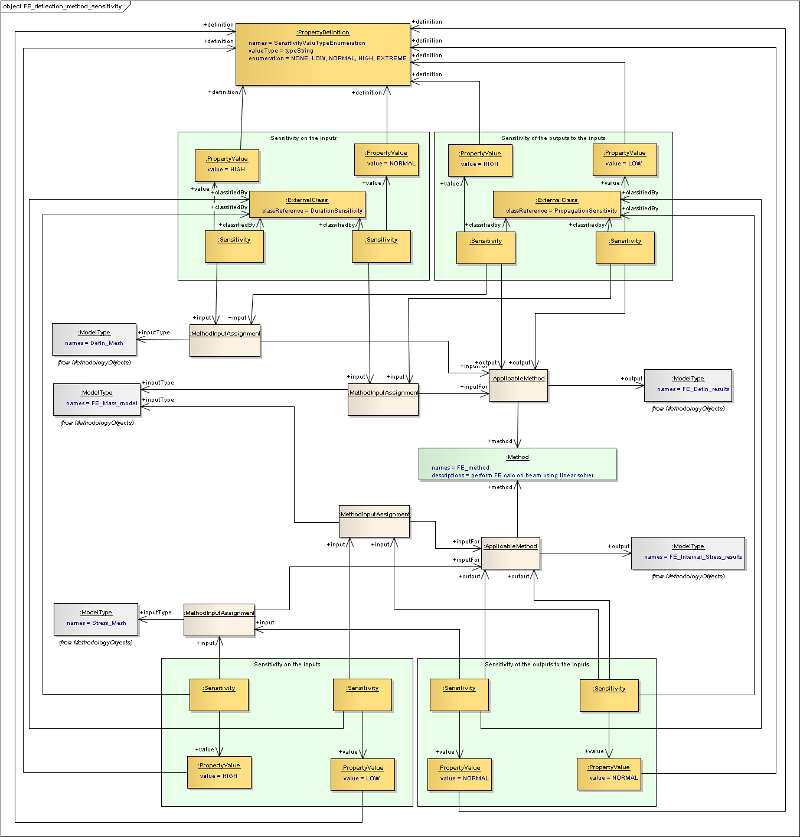

There are then two alternative ways to compute the deflection. The first is using a simple formula in a spreadsheet. This has several assumptions, or limitations, in that it is only applicable for prismatic shapes. The second approach is by using an Finite Element analysis. This can work on any solid shape, and it is probably over-kill for this example so can be used to illustrate a poor “utility” rating.

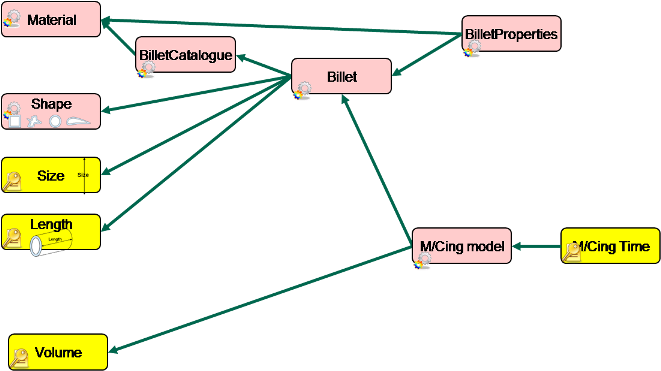

Manufacturing AMN¶

Finally there is a stage that brings in some manufacturing issues. Here the scenario is, that depending on the size of the beam, different billet sizes have to be used, and these have different material properties (Youngs modulus) due to the roll characteristics of the forging process

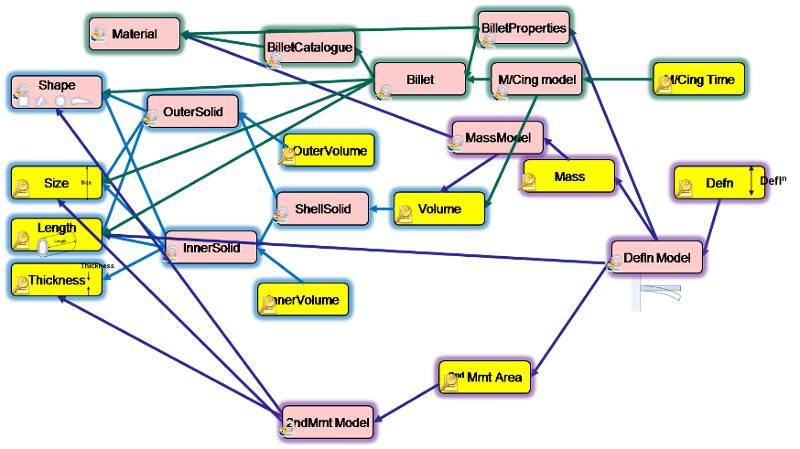

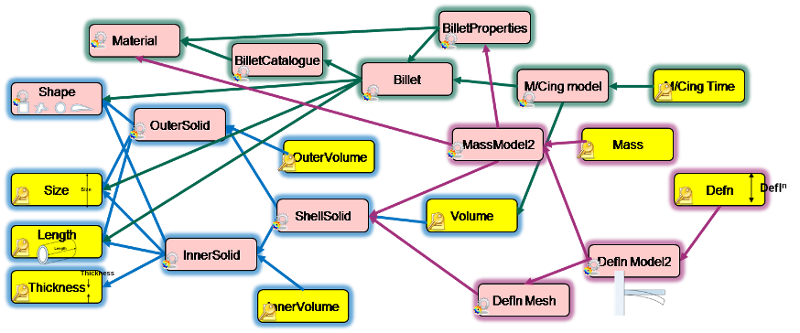

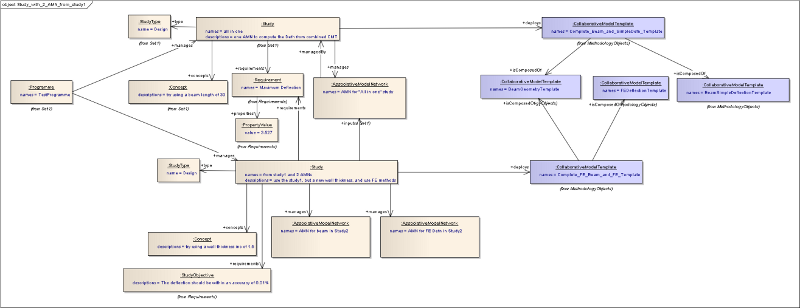

Combined AMN¶

These stages can be combined into a single picture, which are illustrated below using either the spreadsheet, or the Finite Element method of calculating the deflection.

Links and images used in other pages¶

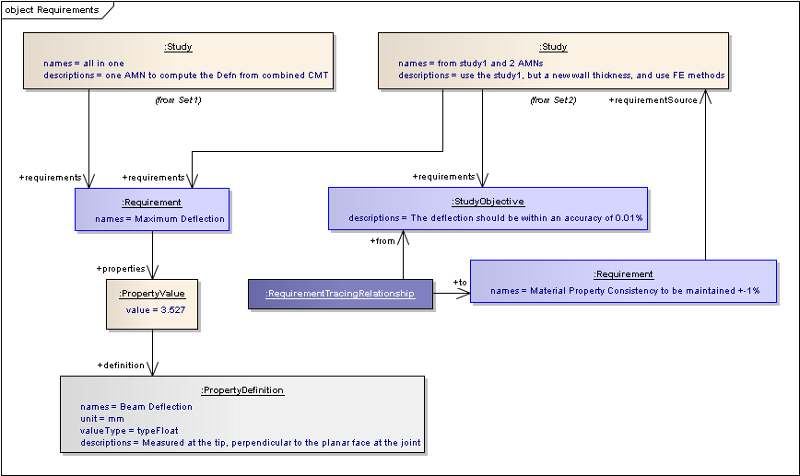

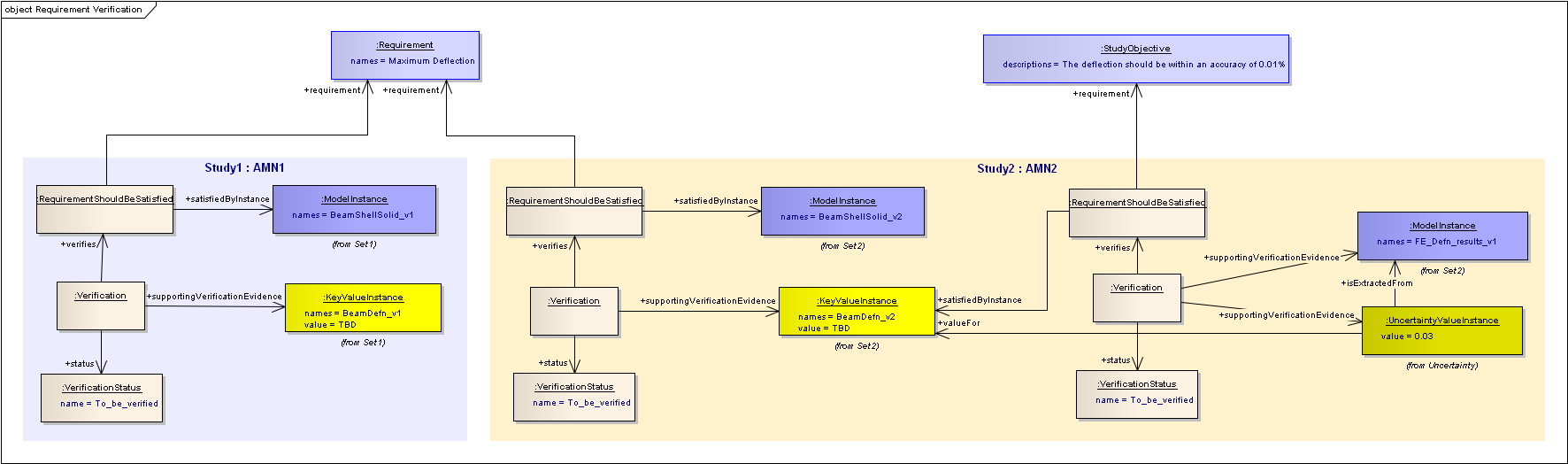

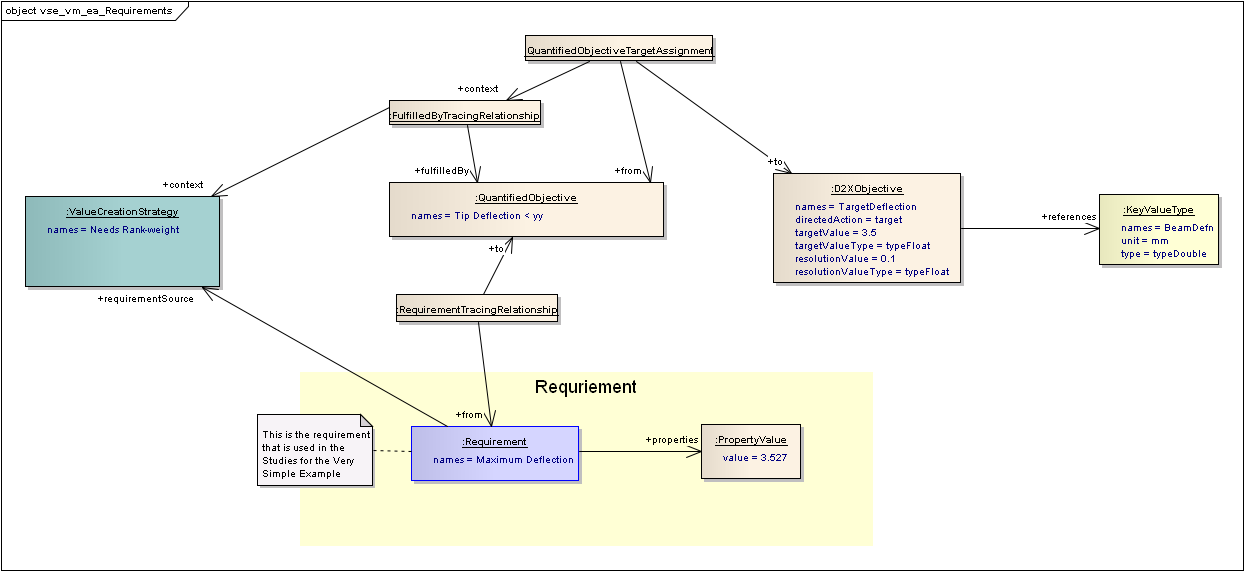

Requirements and Verification¶

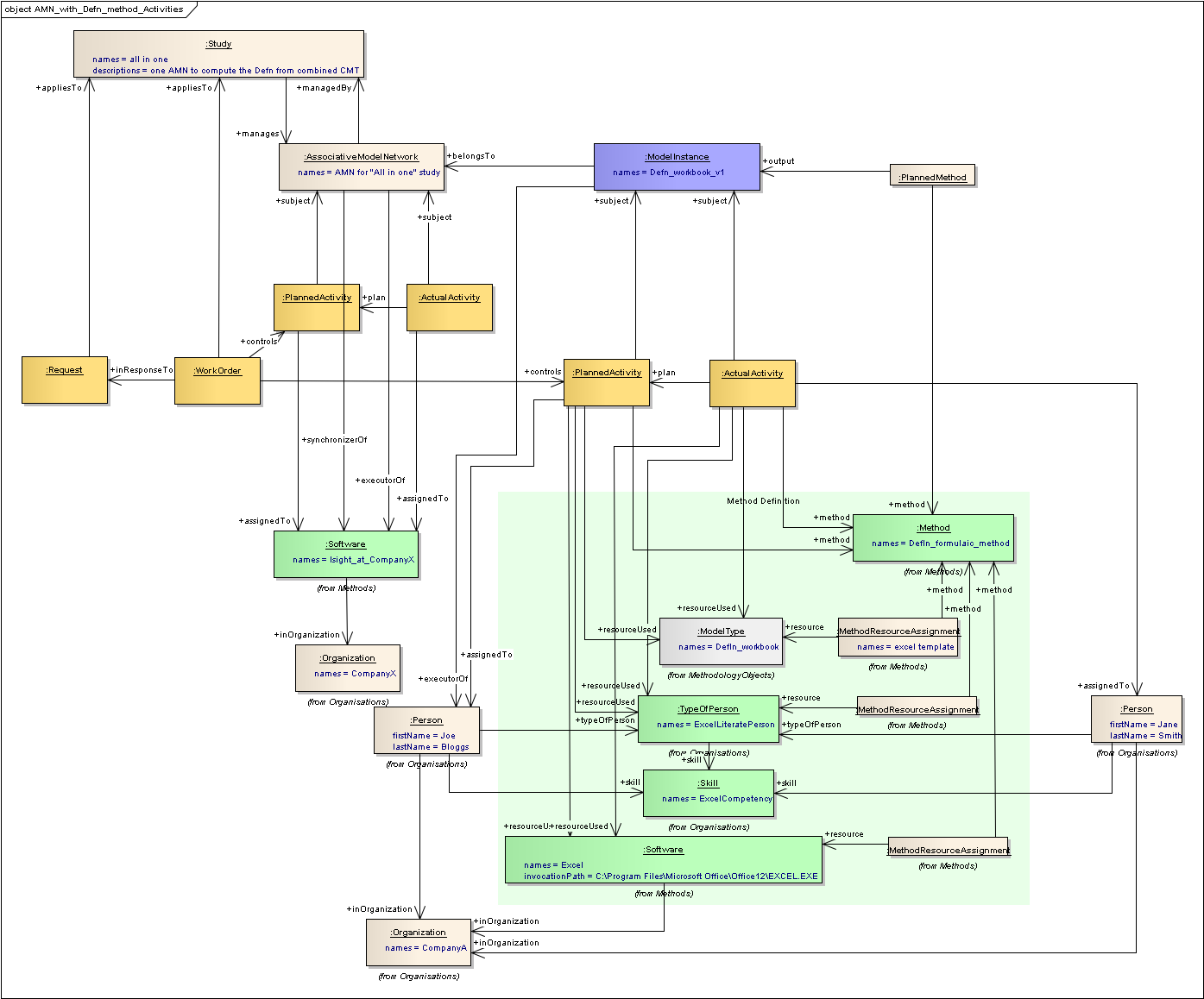

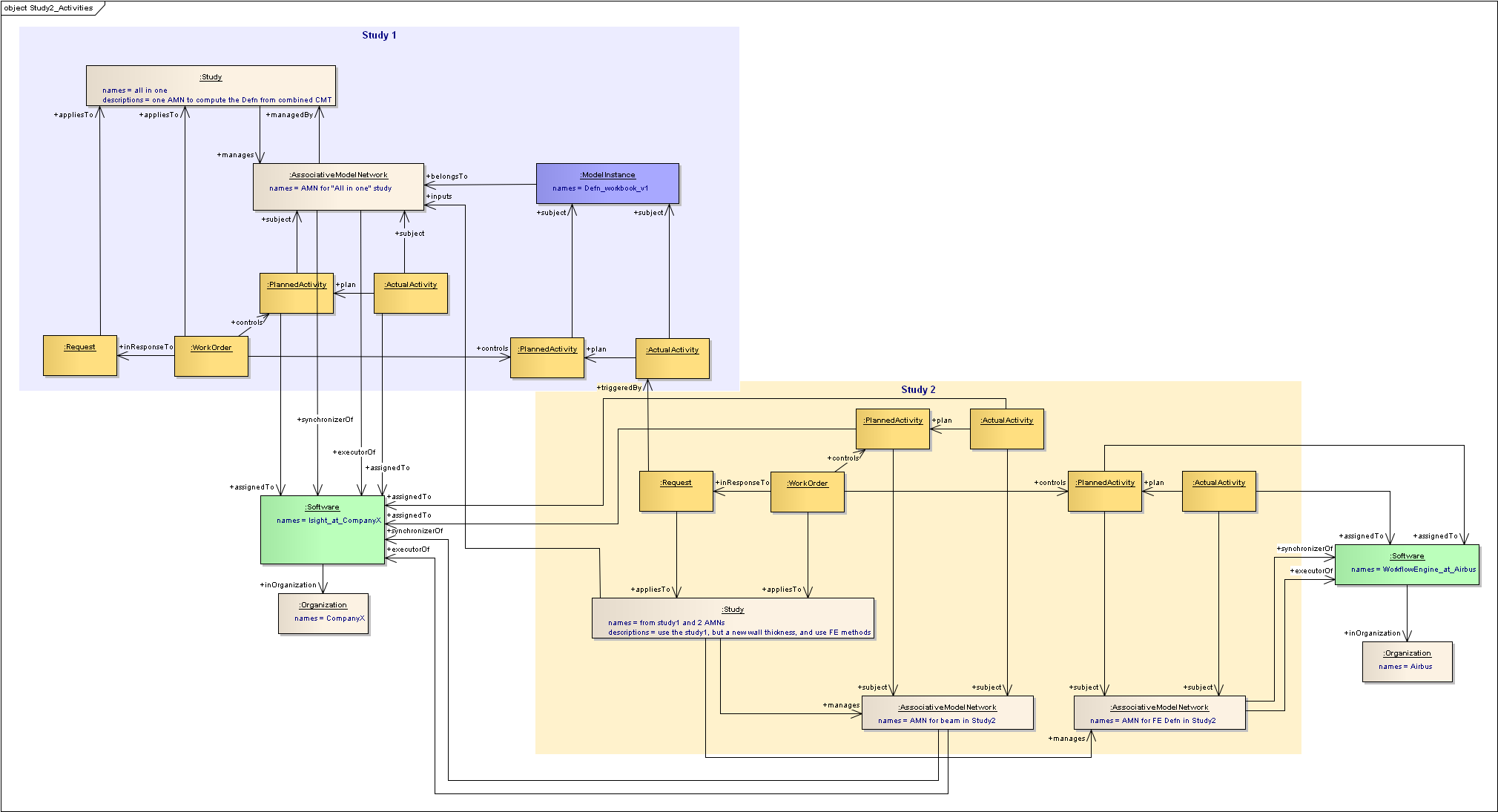

AssociativeModelNetwork and workflow¶

See AssociativeModelNetwork and workflow

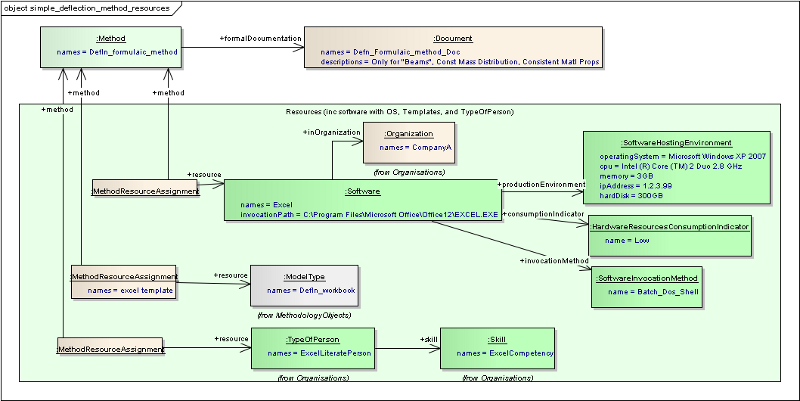

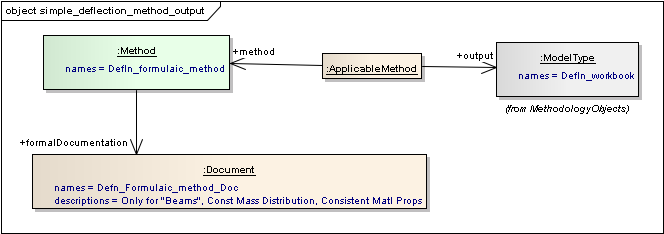

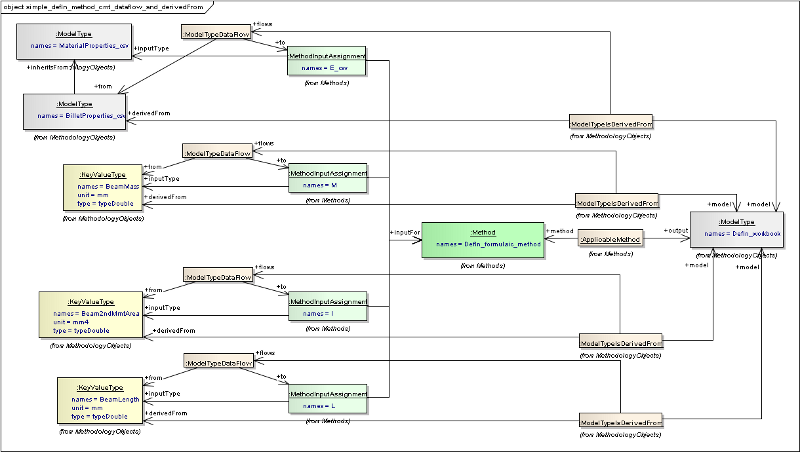

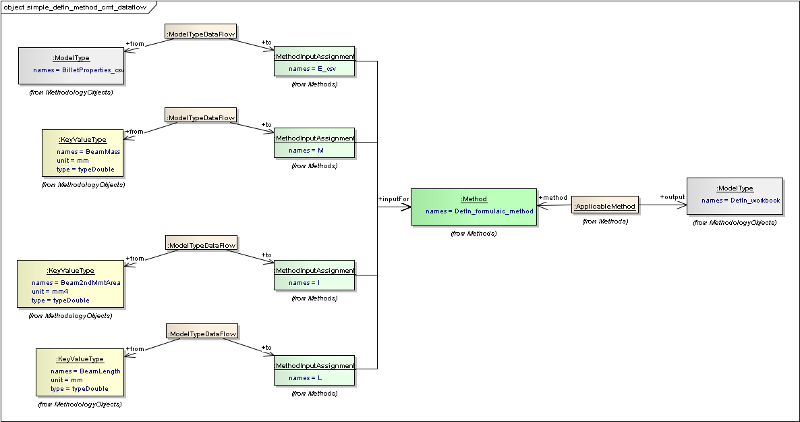

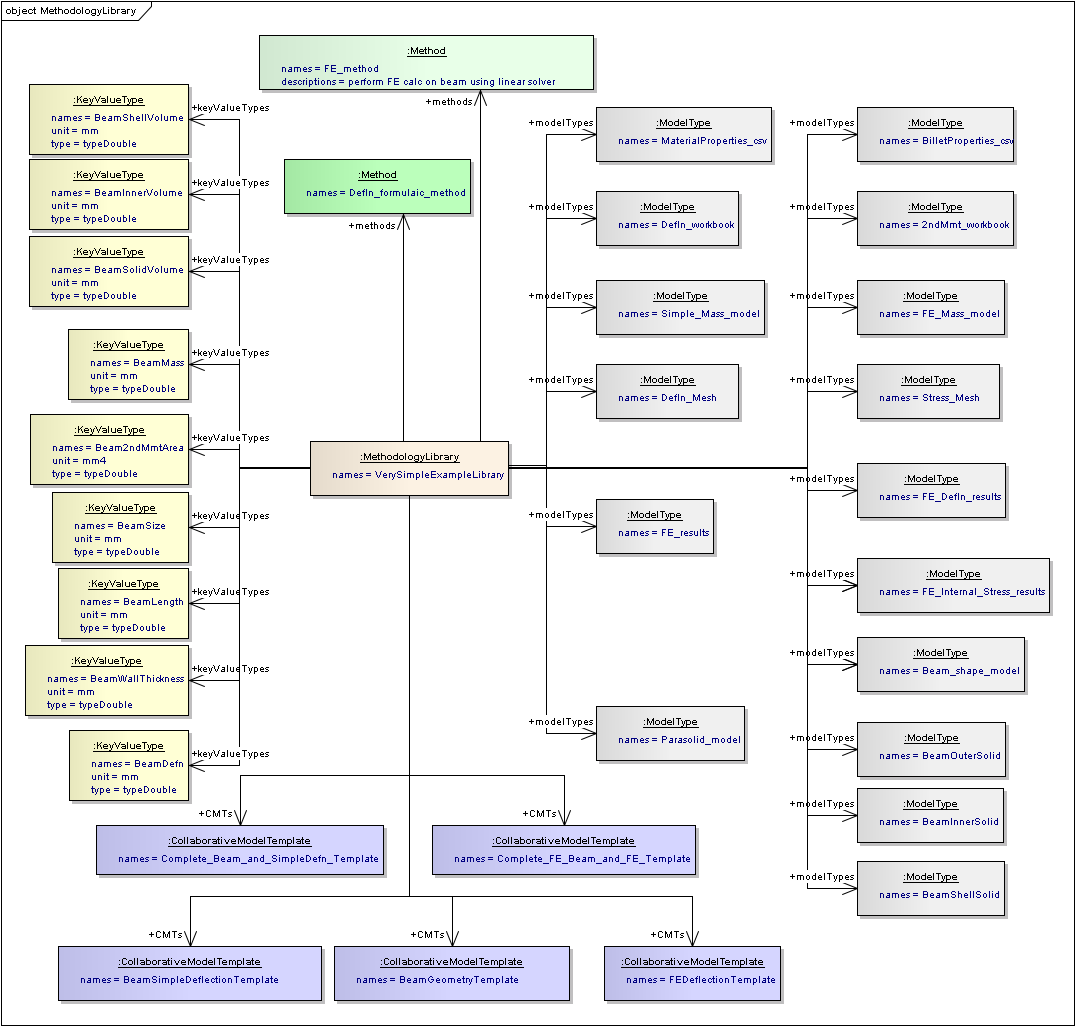

Method Definition¶

Methods DataFlow¶

See Methods DataFlow

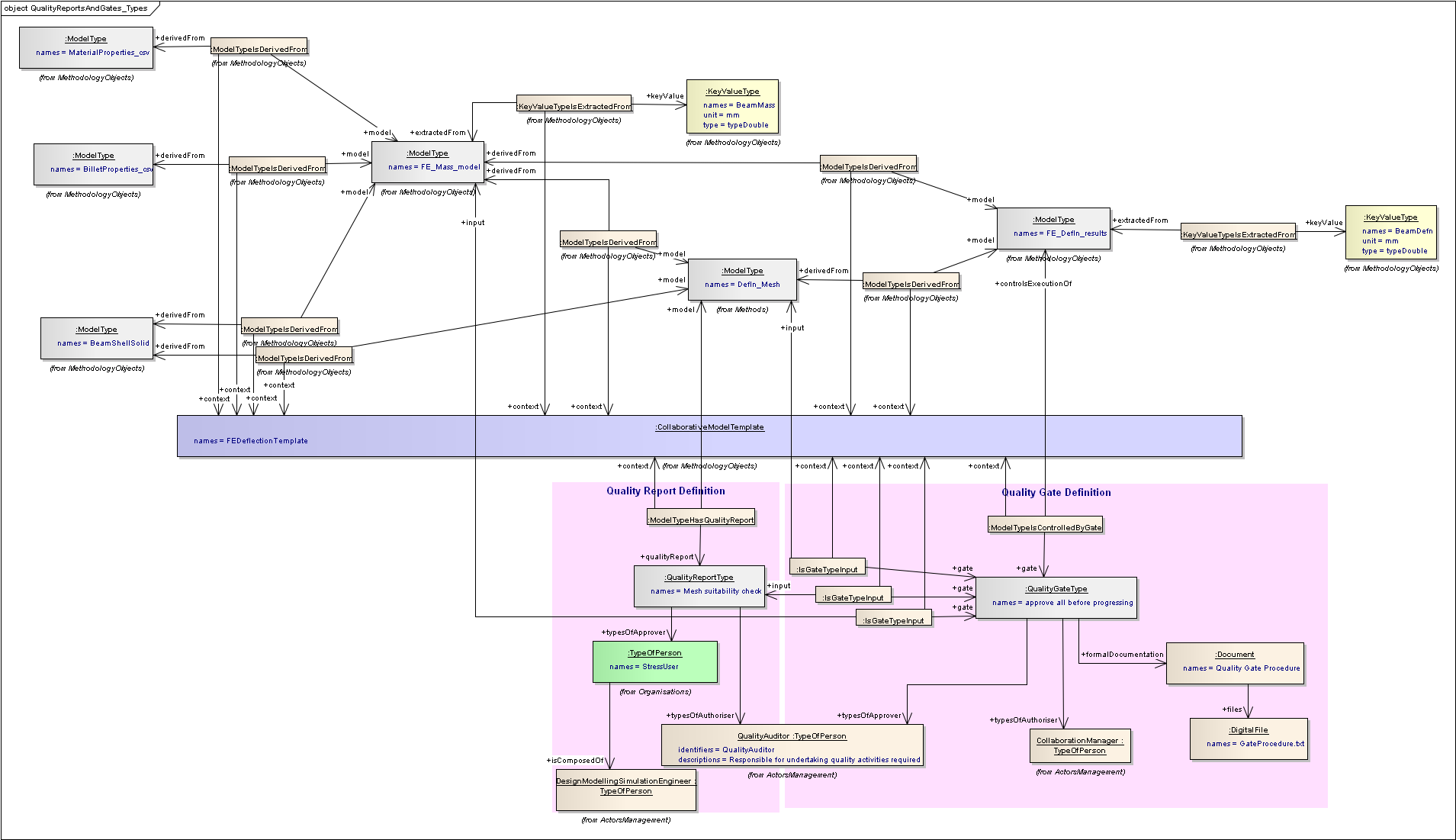

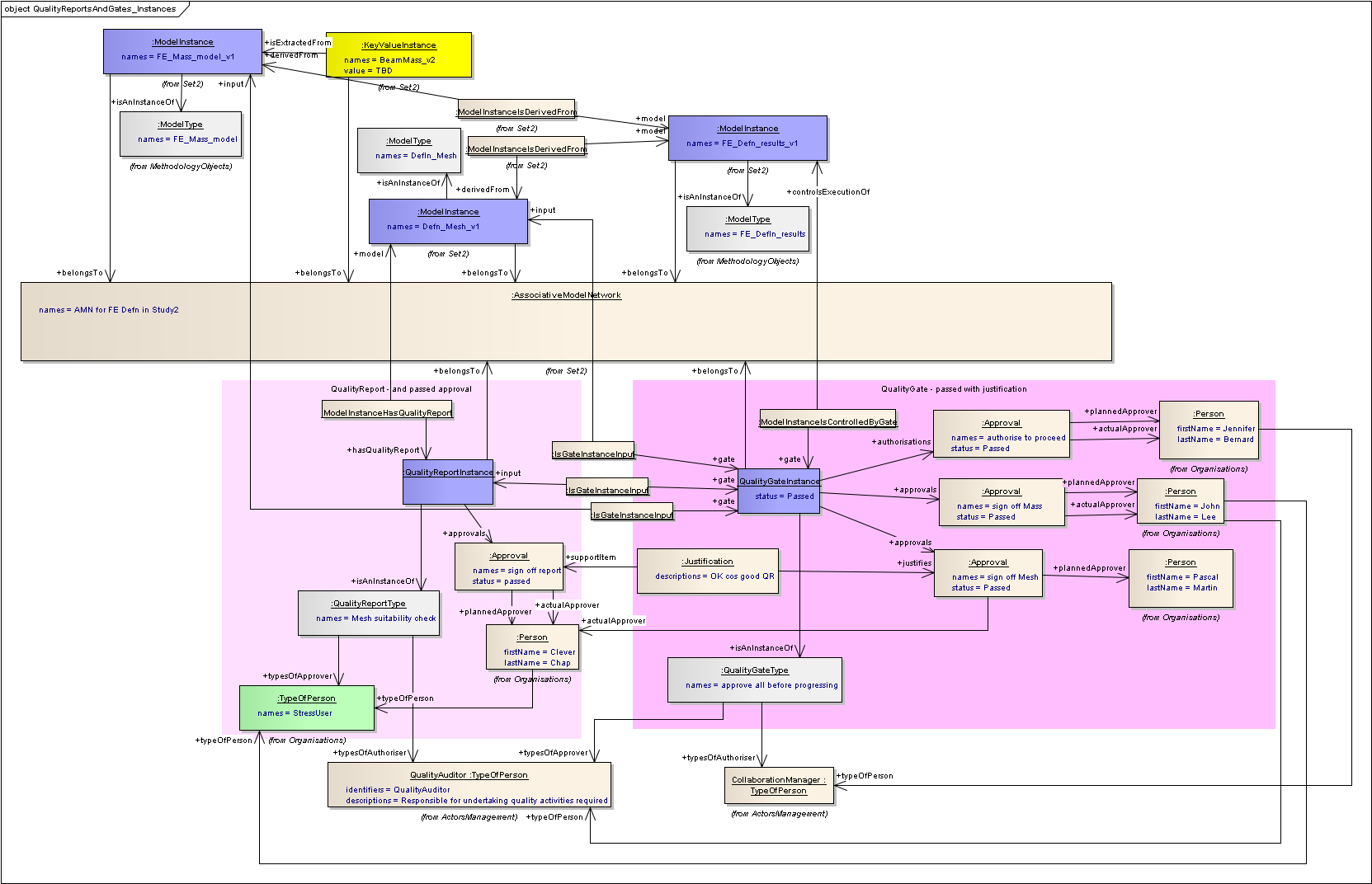

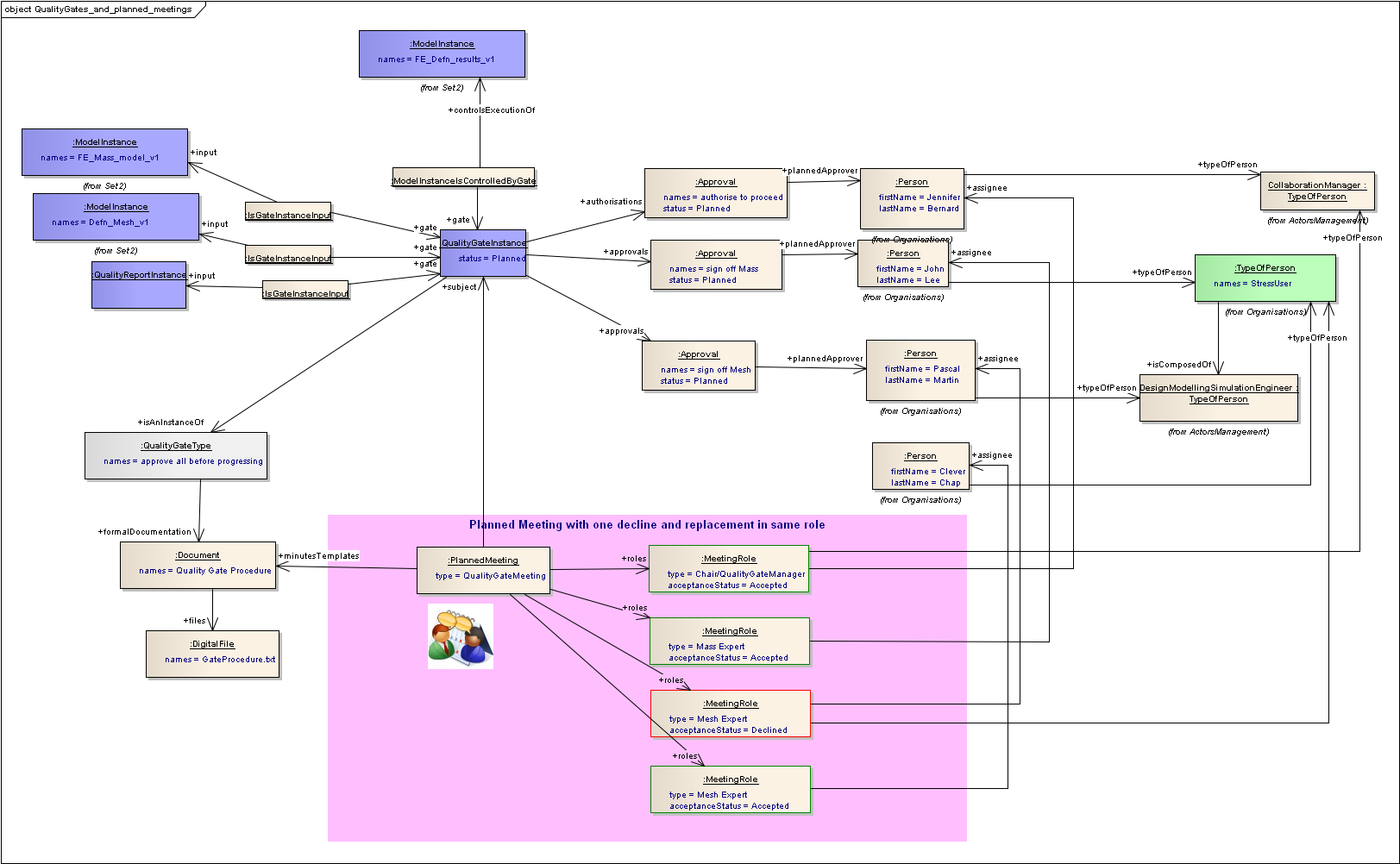

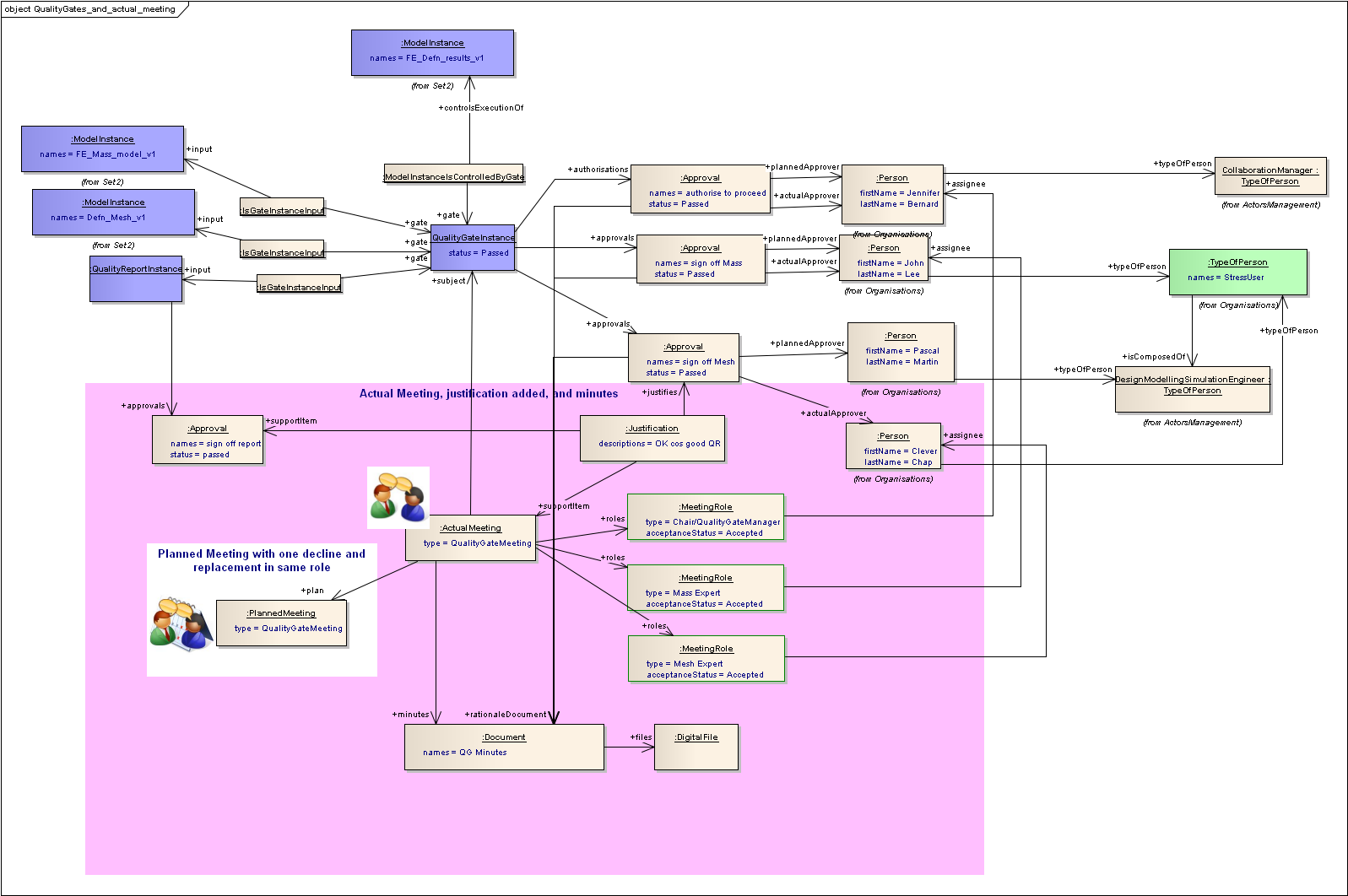

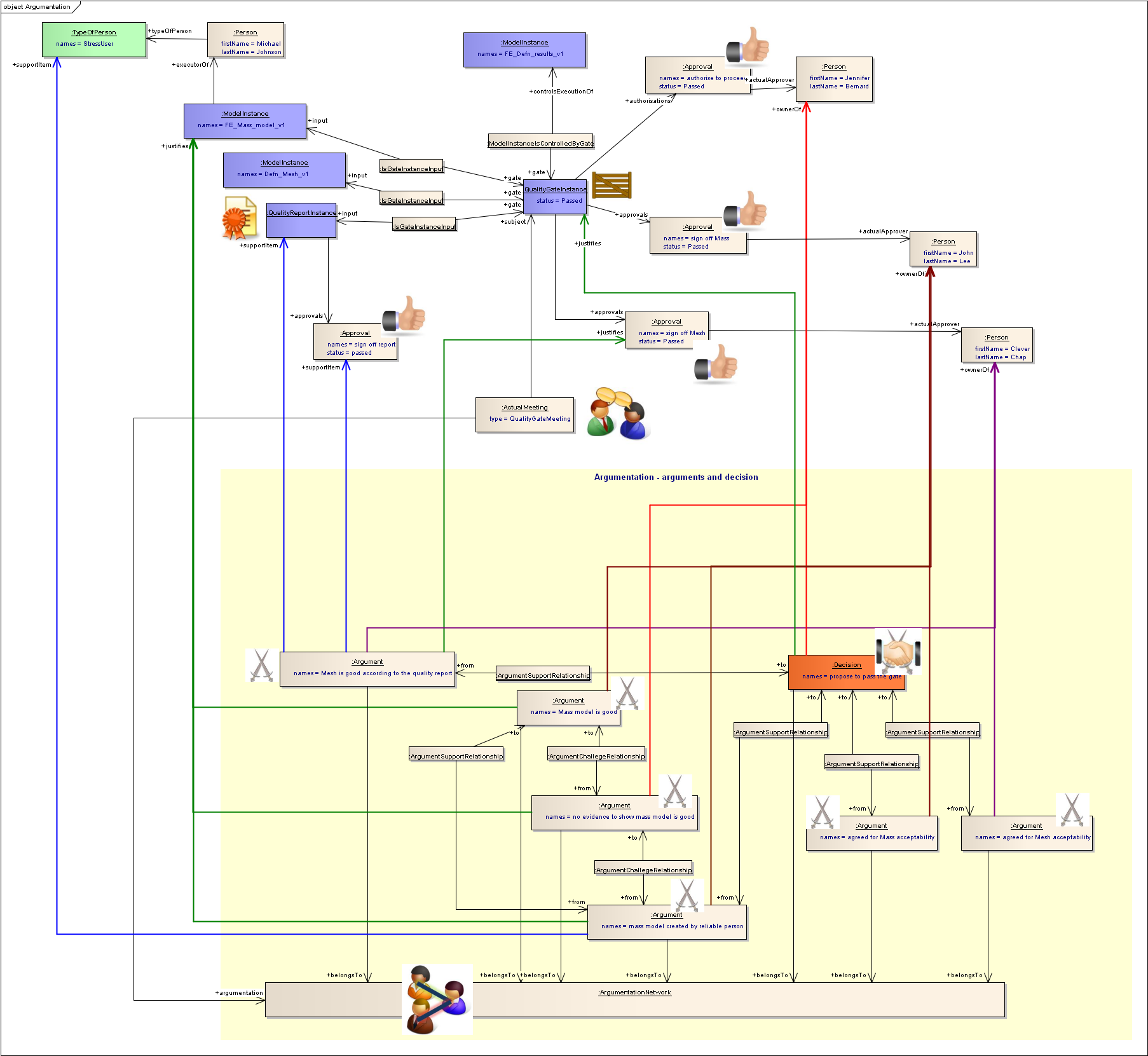

Quality Gates¶

See Quality Gates

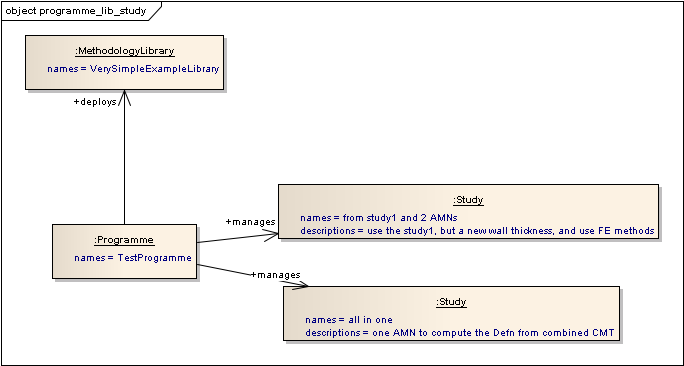

Templates and Instances¶

Collaborative Process Management¶

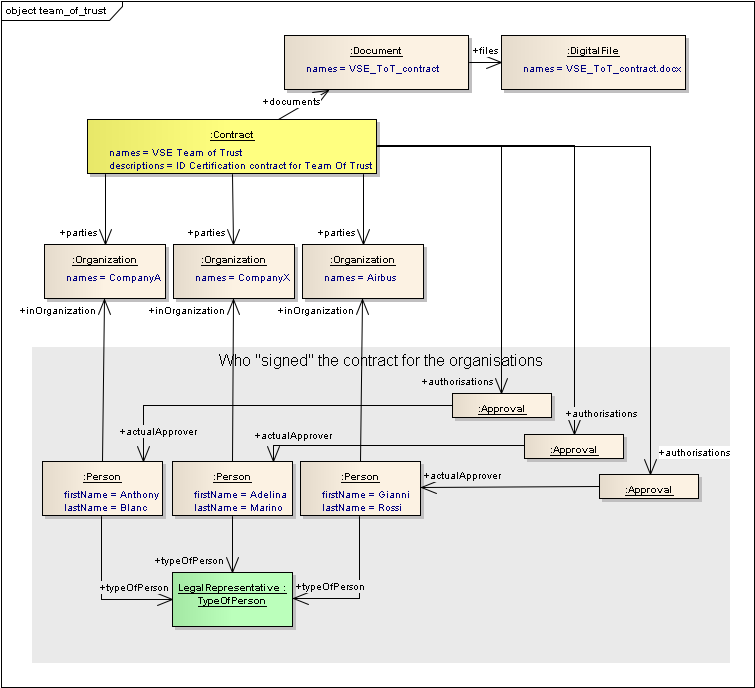

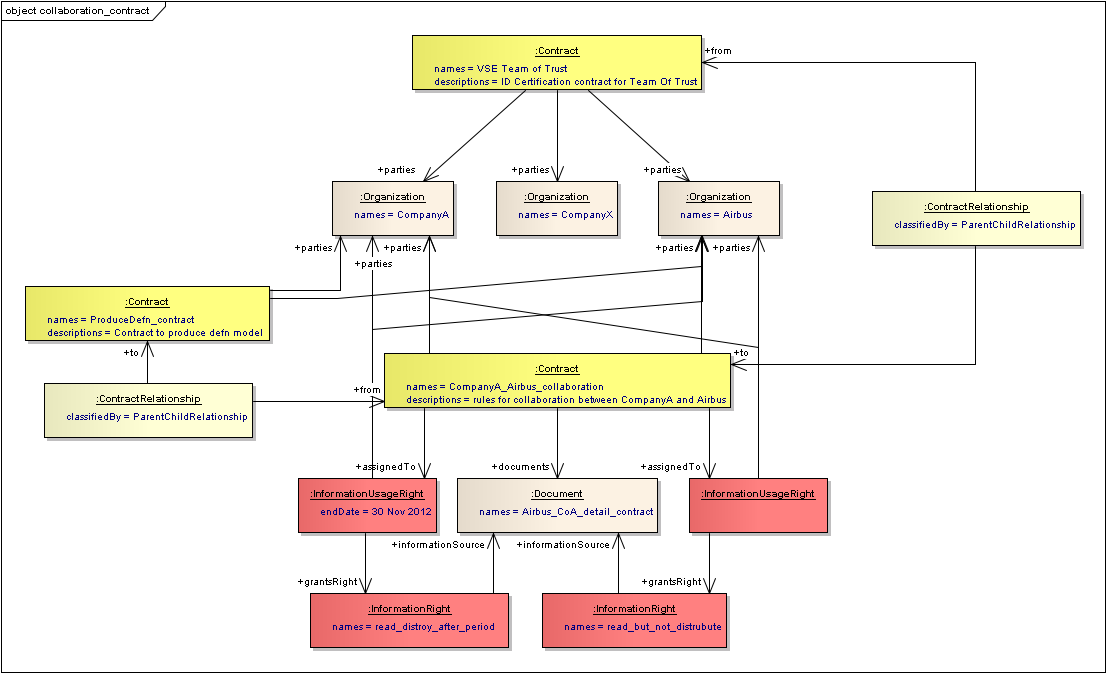

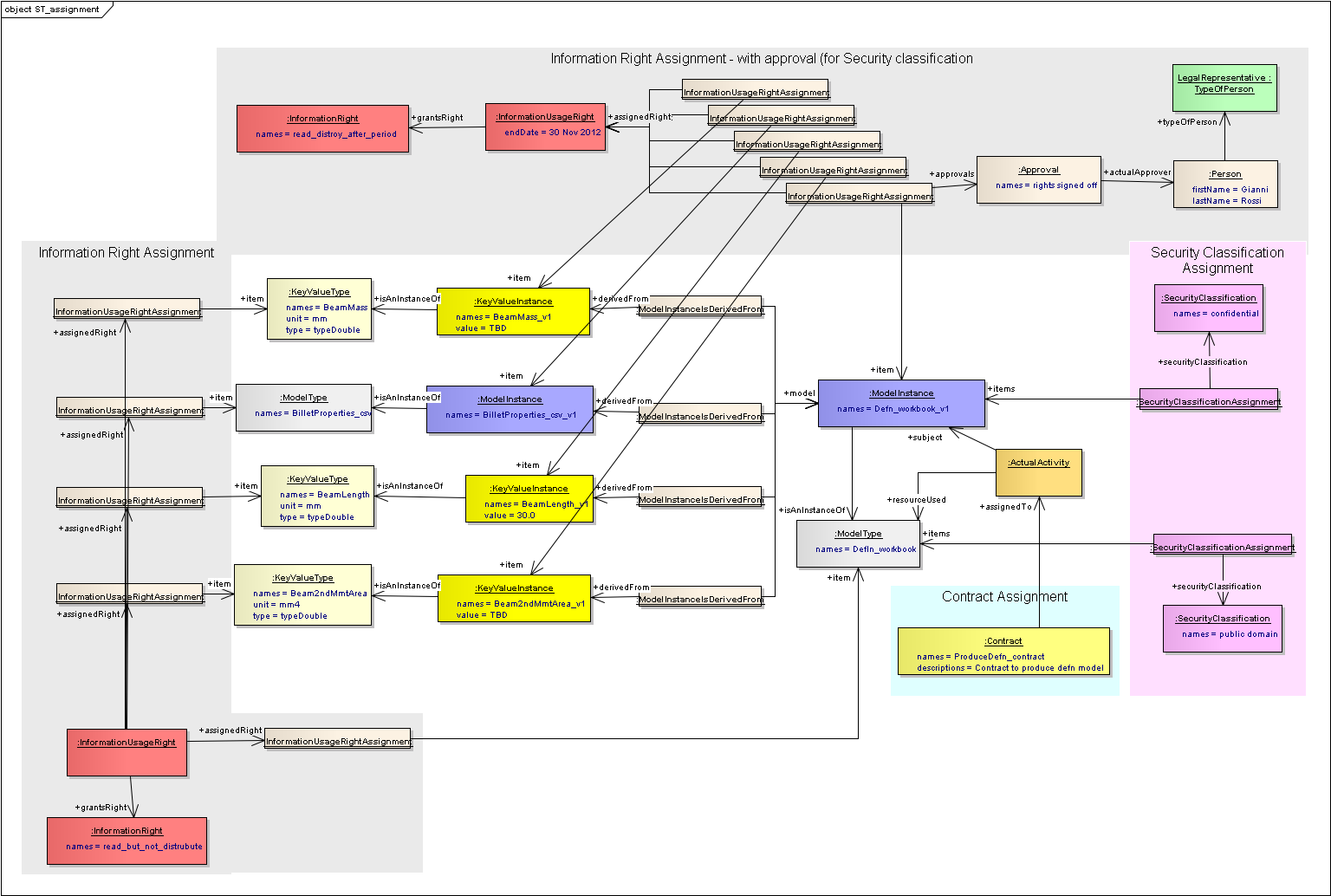

Security and Trust¶

Assignment of Information Rights and Security Classifications

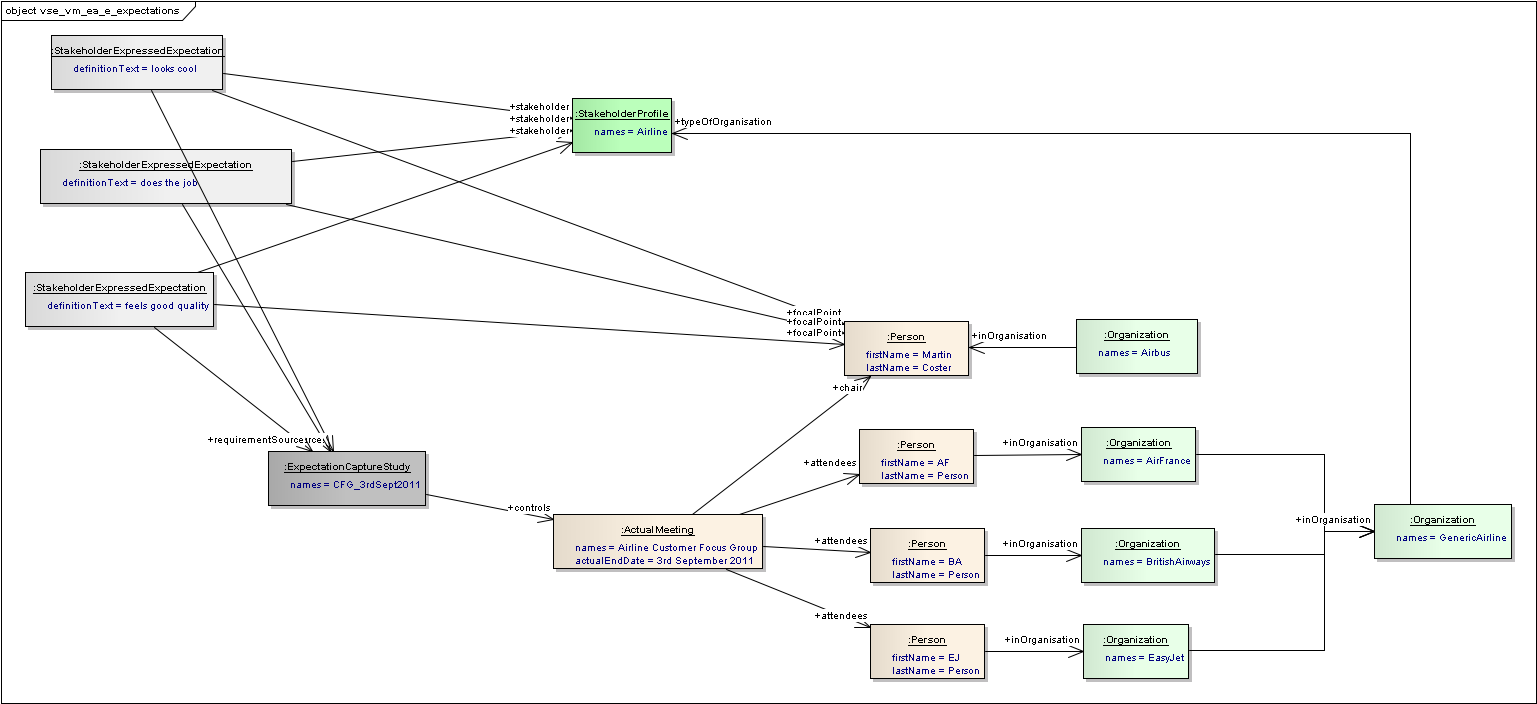

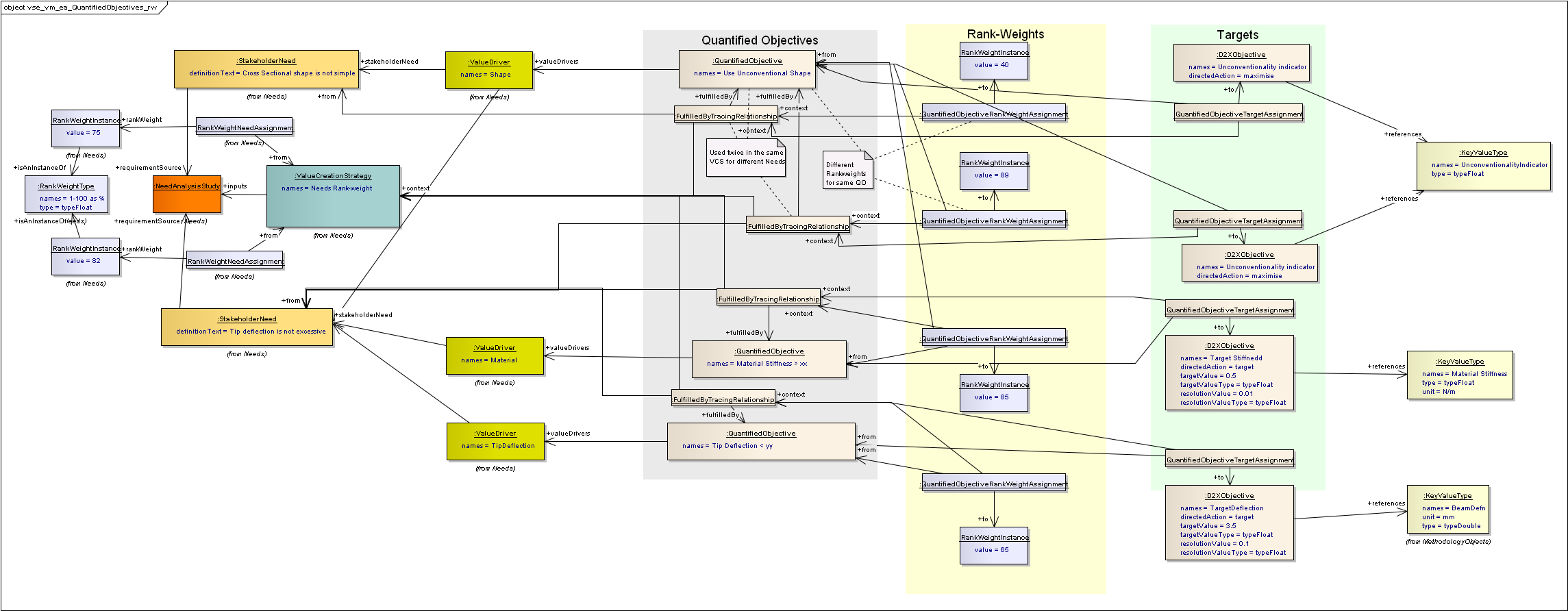

Value Modelling¶

See Value Modelling

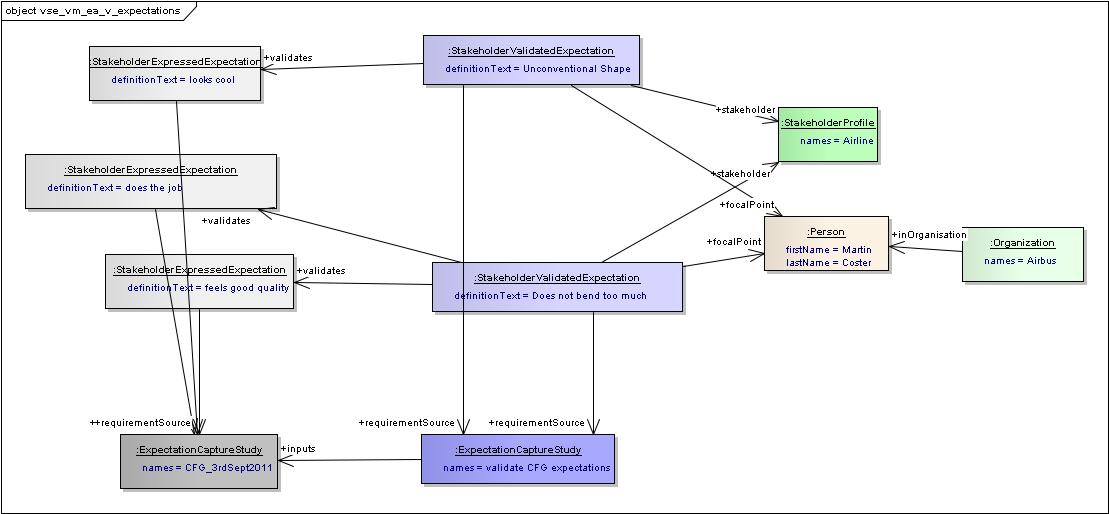

- 1a. Stakeholder expectations are captured and validated

- 1b. Stakeholder expectations are validated

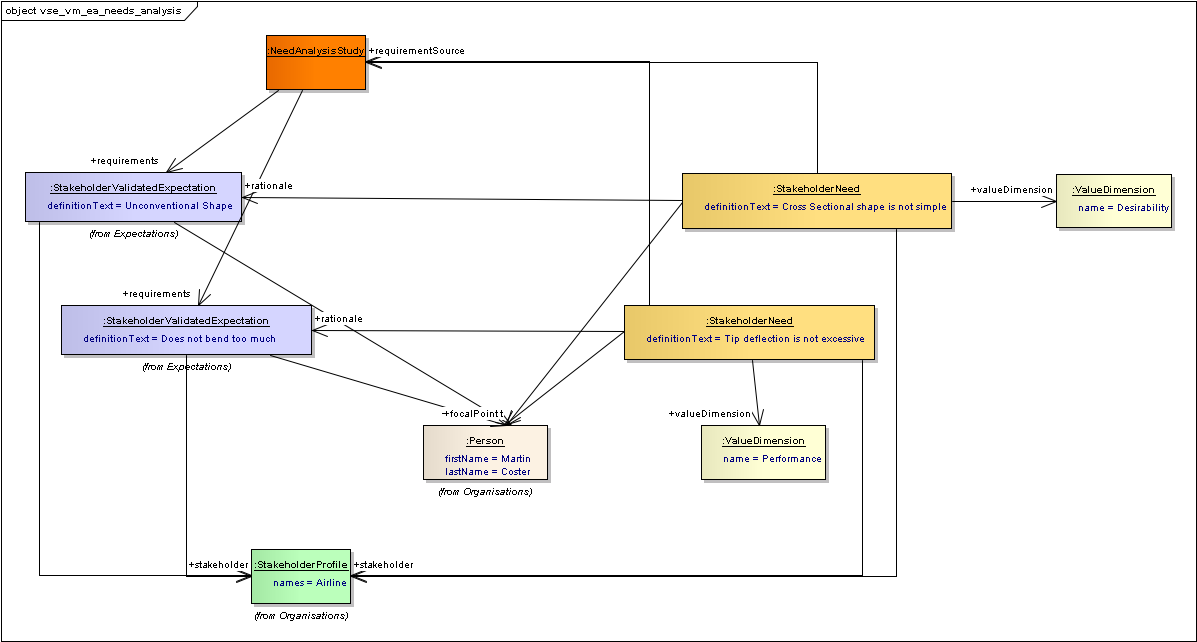

- Stakeholder needs identified, analysed

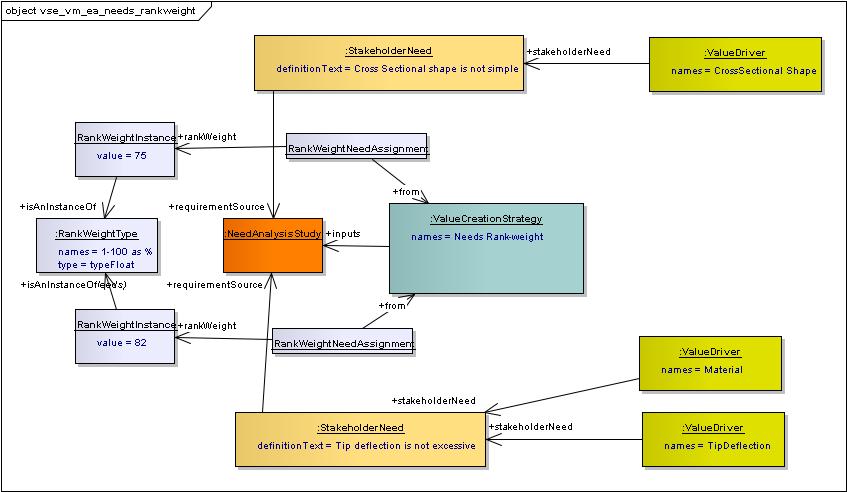

- Value Creation strategy for analysed and rank-weighted Needs

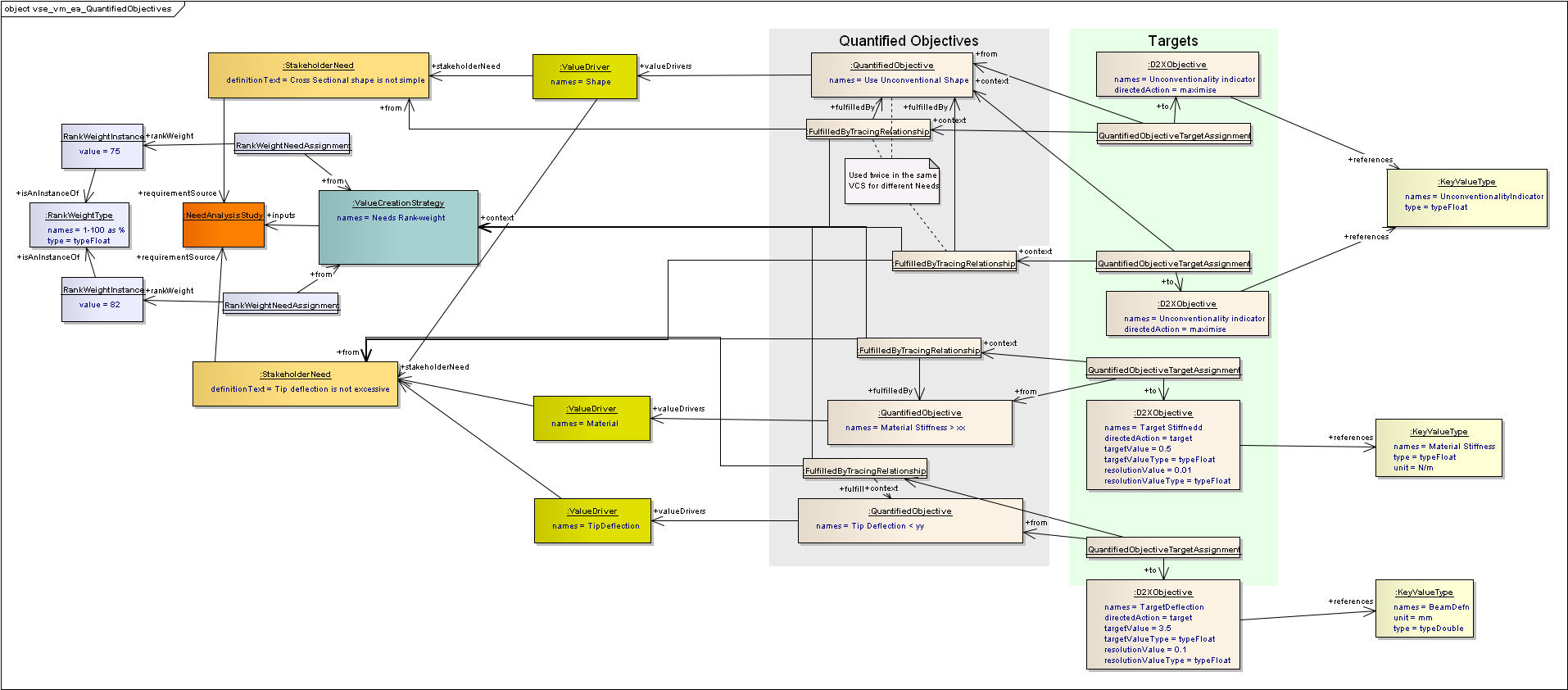

- Quantified Objective Hierarchies with targets for analysed and rank-weighted Needs

- Value Creation strategy for analysed and rank-weighted Quantified Objectives

- Value Models developed

- Requirements established based on rank-weighted quantified objectives

Section author: Judith Crockford